NCG CAM v17.0 Updates UI with Ribbon Design

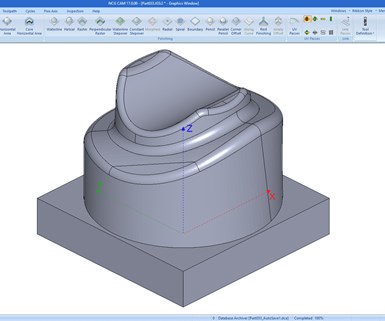

NCG CAM v17 features an updated user interface whose ribbon design organizes the program into a series of tabs at the top of a window.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

NCG CAM v17 features an updated user interface whose ribbon design organizes the program into a series of tabs at the top of a window. According to the company, the new ribbon layout will make it easier for the user to discover new features and functions.

Dynamic Material Removal has been added alongside the existing cutter animation function. It can indicate the direction of milling (climb or conventional) and identify any gouges or collisions. The feature is said to enable better visualization and verification of the material stock removal produced by the calculated tool path.

The software’s Drilling Hole Shape Database and Compound Drilling Cycles can create a searchable database of hole shapes. Several cycles can be grouped together as compound cycles to apply them to specific hole shapes. The Compound Drilling Cycle can also be applied to holes of different directions (tool axis) so that holes with different directions but the same hole shape can be programed in one step.

The Coordinate System module has been extended to include axis rotation information. The user can create a points folder containing key reference points and define the orientation. The module then repositions the imported part(s) or tool path(s) to the selected plan.

Another new feature enables the user to project a 2D boundary onto the surface. 3D curves can now be projected from a 2D boundary. This is mainly aimed at 3+2 five-axis machining, since existing boundaries are drawn above the surfaces along the tool axis, the company says.

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.jpg;maxWidth=300;quality=90)