Metrology Software Update Enables Roundness Measurement, Analysis

Digital Surf’s Metrology 4.0 software now enables both measurement and analysis on the Taylor Hobson roundness instrument series.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

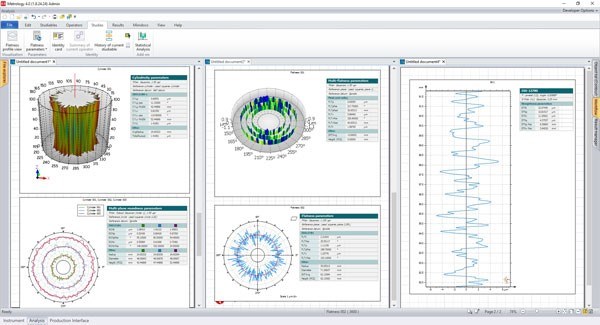

Metrology 4.0 software in use on the Talyrond 500 Pro.

Photo Credit: Taylor Hobson.

Digital Surf, a provider of surface analysis software solutions and Taylor Hobson, a leader in surface and form metrology, recently completed a new round of co-developments resulting in the release of an updated version of Metrology 4.0 software with the manufacturer’s brand new Talyrond 500 Pro, an instrument for roundness metrology.

Metrology 4.0 software made its debut in 2018 with the PGI Novus series of surface instruments, and now also enables both measurement and analysis on the Taylor Hobson roundness instrument series. Mountains platform software features are said to be seamlessly integrated into Metrology 4.0, which enables better control of the measurement process and the direct creation and export of analysis documents.

Users working with roundness now have the ability to progress from measurement to reporting within the same interface, whcih the company says makes the metrology process simpler and more straightforward. This is said to be particularly useful in a production context.

Specific features include high-quality 3D visualizations of cylinders and flatness scans, ease-of-use and desktop publishing, enabling users to create personalized analysis documents showing raw measurements and analysis steps performed. Using the multi-instrument compatibility of Metrology 4.0 software, various measurement types can be represented on the same document; for example, roundness, flatness, cylindricity, surface finish and contour.

“Cooperation between Digital Surf and Taylor Hobson goes back almost 30 years,” says François Blateyron, director of research & metrology at Digital Surf. “Both teams understand each other. Our development department was able to build on its robust scientific knowledge to adapt to the new challenges of roundness metrology.”

Related Content

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

.png;maxWidth=150)