Latest Software Version Features Multi-Axis, Mill-Turn Advancements

IMTS 2022: The company says one of the software’s top improvements is the ability to consolidate multi-axis toolpaths.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Photo Credit: CNC Software

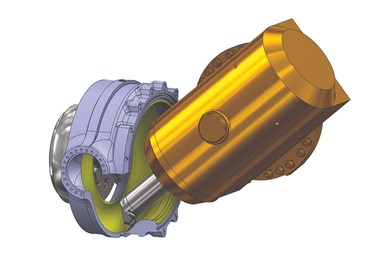

CNC Software’s Mastercam 2023 features multi-axis, mill-turn advancements, which were directly driven by feedback from Mastercam users and shops.

One of the top improvements is the ability to consolidate multi-axis toolpaths. Morph, Parallel, Along Curve and Project Curve are no longer individual toolpaths in Mastercam 2023. Instead, the Unified toolpath enables access to these cut patterns when users add the appropriate curves. For example, to create a toolpath that morphs between two surfaces, users select Unified from the Multiaxis toolpaths, and then set the Cut Pattern to two surfaces with the Morph style.

Users can also now detect undercut stock when machining. The Dynamic OptiRough and Area Roughing toolpaths can now be aware of undercut stock conditions, resulting in improvement to the toolpath motion, including less air cutting.

The software also features a new B-Axis contour turning toolpath added to the Turning suite for the Mill-Turn product. B-Axis Contour Turning is a finishing toolpath that enables rotation of the B-axis while the tool is cutting. The toolpath features a top-down workflow and provides users with either Automatic or Manual motion control. Automatic mode is said to produce safe toolpath motion that keeps the insert in contact with the contour. Manual mode offers full control over the B-axis angles along the contour.

Related Content

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

.png;maxWidth=150)