Share

Takumi USA

Featured Content

View More

Listen to the fifth episode of season two here, or visit your favorite podcast platform to subscribe to “Made in the USA.”

Catch up on season 1 here.

Richard Worsham, Co-Founder of Janus Motorcycles: We do get lots of questions from people like how in the world do you expect me to shell over handmade American price? And then it has this Chinese motor in it. We tell everybody hey, if you know of a small simple single cylinder carbureted engine made in the States, you let us know. We'll explore it, but at a certain point, it becomes a kind of a moral imperative. And I mean, at a certain point, you're not going to really convince some people. Never in my wildest dreams would I imagine that it would be the sort of bearded Amish guys, all of our the parts that they make for us, they're not running off the grid.

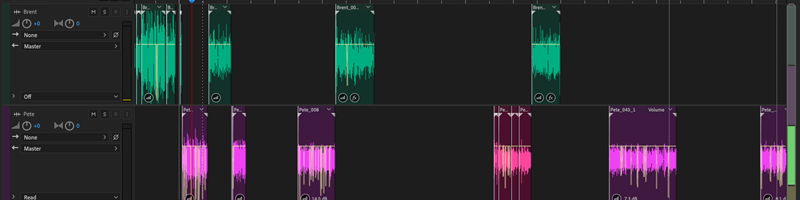

Brent Donaldson, Editor-in-Chief of Modern Machine Shop: Welcome to Made in the USA, the podcast for Modern Machine Shop magazine that explores some of the biggest ideas shaping American manufacturing. I'm Brent Donaldson.

Pete Zelinski, Editorial Director of Modern Machine Shop: I'm Pete Zelinski. This season of Made in the USA has focused on manufacturers that are at different points on a journey to bring back or keep production within the United States. The motives behind these companies decisions are varied. They include pragmatic and logistical considerations about supply chain distribution, concerns about intellectual property theft, the loss of brand reputation and customer loyalty, as well as what a former guest on the series called feelings of economic patriotism. Of course, there are plenty of American durable goods manufacturers, or more specifically, there are plenty of owners and leaders of these companies that aspire to keep production in the United States, but feel as if they've hit a wall. That they've reached their practical limit when it comes to sourcing parts in the US versus outsourcing to a lower cost country.

Brent Donaldson: So this season started with a story about an American motorcycle company that reshored nearly all of its production from China. And now we're going to bring you a much different story about a much different American motorcycle manufacturer, a company called Janus Motorcycles. So if you go to Janus' website, the company clearly outlines where each of its parts are sourced. Its top-selling engine is a 229 cc air-cooled single-cylinder two-valve pushrod motor from a manufacturer in China. And you'll get to hear why the company's co-founder, Richard Worsham, makes no bones about it being the best choice of engine for his line of Halcyon 250 motorcycles. But outside of the engine, most of the bike’s parts are made in the USA and not just the US, but within the most extreme version of a hyperlocal supply chain I think I've ever seen.

Pete Zelinski: And for that, you can partly thank Northern Indiana's status as the RV capital of the world and partly thank the region's large population of Amish residents. Several of Janus Motorcycles’ core components and assemblies are either produced in-house or with the help of nearly a dozen suppliers that operate within a five-mile radius of the company's headquarters in Goshen, Indiana. Every day, sometimes twice a day, a Janus employee makes what's referred to as the milk run. The milk run is when a Janus employee, aka the milkman, takes the company's 23 year old black Ford Econoline van on a loop around the patchwork of farmland surrounding Goshen, stopping at several suppliers to pick up and drop off parts. Some of these suppliers are Amish, some non-Amish suppliers work out of a barn and some are what most of us would consider to be typical machine shops and production facilities. Regardless, the craftsmanship that goes into these locally produced parts is world-class, which helps explain why a Janus Halcyon is among the most expensive 250 cc motorcycles in America.

Brent Donaldson: So I had the pleasure of making the milk run with Janus co founder and milkman for a day, Richard Worsham, and you'll hear sound bites from that experience scattered throughout this episode. In the meantime, here's Richard, we'll see you on the other end.

Richard Worsham: Hello, my name is Richard Worsham and I am co-founder and designer at Janus Motorcycles. My accent is, although often mistaken for a Canadian accent, from Tidewater, Virginia where a long diphthong oh you out and about is an expression. Janus Motorcycles is a small volume production motorcycle manufacturer based in northeastern Indiana, and we build handmade small displacement, which means lightweight, lower powered motorcycles that are really unique in the fact that they're very locally made and very handmade and that they look like almost nothing else on the road. A lot of people when they see our bikes would describe them as looking classic or even old-fashioned. Our main model, the Halcyon, the design harkens back to automotive designs from the 1920's and 30's. So it's something that looks very classic, sort of like if you're familiar with Indian motorcycles, or Harley Davidson motorcycles, it is reminiscent of those. Current production, total volume, last year, we did almost 300 bikes this year, we're shooting to be maybe a little over 300. This facility, we call HQ, is an old dry cleaner building, literally in the heart of Goshen, or behind the theater, the coffee shop and the record store, across from the City Hall and the police station, we're surrounded. But really what this location has always been and will always be, even as we grow or may actually become even less than that, is assembly, it's final assembly and pre assemblies. So we actually do pinstriping, but that really is kind of a very last in the train of a parts finishing. So we'll do pinstriping, purchasing, final assembly, pre assemblies, testing and then all of our sales and marketing and design is here. When we launched the 450 model about two years ago now, we opened a fabrication plant, about a mile and a half south of us, still within the city of Goshen, a really kind of a really urban location, beautiful old manufacturing plant. And at that location, we do all the 450 chassis fabrication, so that involves tube bending, welding and then also we brought all of our fender manufacturing. And that's actually a really good example of another local process that we decided that local wasn't even good enough. We had all of our vendors for the first eight years, nine years of the company made up in Elkhart, which is about half an hour north of us. It's an roll forming process that they were using, a company that used to make all the parts for the continental kits on the backs of a conversion vans. And it worked really well. But it was a little too big for us and our small orders, we had to order a lot of parts. And they were kind of bending over backwards to make it work for us, great people that were motorcycle enthusiasts, but it didn't make a huge fit. So we actually made it even more handmade, we use an old Swedish pull max and a planishing hammer and hand make every single fender and interestingly enough, it's more cost-effective than doing it the way we did it before because we can control the quality there when they come off that machine. They are ready for paint, whereas the other ones took all kinds of work to get them ready for that. So it looks really good. It's a great marketing thing as well. It's a lot of fun. The bodywork is all made by hand. Our fuel tank is hand-formed aluminum, our fenders are all handmade on a vintage machine and then they're all pins hand pinstriped. So it all kind of comes together to really create a kind of striking unique look that is very different from the kind of common plastic look that is found on most modern contemporary motorcycles. And one of the interesting aspects of Goshen is that it's sort of nestled in Amish Indiana country. So while there are very few Amish in the city, we are surrounded by Amish farmland. Most of those Amish people have come over from the Pennsylvania area of Lancaster, Pennsylvania and populated this area. And many of them actually work in the RV plants that surround us.

Brent Donaldson: So what's our itinerary? Lay out where we're going.

Richard Worsham: Absolutely. So our itinerary is we're going to first of all stop at our fabrication shop. I'll give you a little quick tour down there. And then we'll pick up we'll drop off some parts for them that they're going to work on. This is part of our Kanban tag system to pick up parts from that are headed toward sandblast. And then we'll pick up what we call the inner world, the Amish call us the outer world. First step will be our exhaust guy, check it out. It's a great example of what the guy, a barn behind his house. He's making money. He used to work in a factory and he's been able to pick it all. This is Brent from Modern Machine Shop. He wanted to check out the developer on it and see where we get. I told him a little bit about how we found you and used to work at Southwest.

Janus Supplier: Until the end of last July is when I finally went full time, I've been just doing welding, I started out doing a lot of repairs, and custom work and just grew from there, I ended up getting a couple of production customers, exhaust being one of them. And that's why I say it's time to just hang up the day job. It was from sunup to sundown. And you do that for a period of time but after a while I started saying no.

Brent Donaldson: So you've built out your own space?

Janus Supplier: We've lived here for about nine years here, in April will be nine years. And this is exactly how we bought the place. We haven't built on anything yet, I really want to this year to build out a nice shop out there on the east lawn. But for doing small stuff like this, this does just fine in the wintertime when you want to keep your vehicle warm, it gets a little crowded. But now I'm really happy I got the space.

Richard Worsham: Yeah, so we founded the company the year I graduated from architecture school, didn't even wait that long. And the goal with the company was to create a production vehicle, it was not a custom shop, we've always set that as a goal rather than kind of a one-off operation. What I'm interested in is making a line of something. And by that, I mean a thing that we can produce one after another and make them all the same. To me, that's much more interesting than making a purely one-off art piece. That's not to say that, obviously what we're doing is much more in the realm of art than a production line stamped out, kind of mass-produced item. But combining the kind of artistry with a production system is really what fascinated us. So that was kind of the goal with what we were doing. We've gotten better about talking about our philosophy as we grow with the company. But really, I think it can best be boiled down to we are creating a new category of motorcycles. And that category is something that it kind of defies the common contemporary idea that the value of a motorcycle or a vehicle is derived from the amount of technology that can be packed into it, and the amount of specifications that it has sometimes purely in numbers. So whereas most of the modern manufacturers you're going to see out there today are going to be boasting about how fast their bike goes or how much horsepower it is. Because that's really all they have to boast about. We're boasting about the level of the experience that the bike can provide the rider and honing in on that. And so our bikes are actually in the world of modern bikes, very slow compared to what other people do. They lack all but the most essential technology. And that's actually what we're kind of focusing on and focusing on the handmade nature of the bike and the ability of the bike to create what we think is the central aspect of the motorcycle machine which is a visceral, real experience where the rider is able to be in control of the machine.

A big part of our category is creating an approachable powered motorcycle that is lightweight. Our bikes weigh between 250 and 350 pounds, which in the world of motorcycles is featherweight. And we accomplish that not with carbon fiber and state-of-the-art materials, but rather with paring down the design to kind of a minimal essential design. And so, yes, they're lightweight. They're based around very, very simple power plants and systems that are very, very easy to maintain. And so that ease of maintenance is a big part of that when I say the Motorcycle Experience, or the experience of riding or owning a bike, being able to maintain it yourself, and actually be able to maintain it, maybe between across generations, is our goal. Our initial strategy with being able to produce a roadworthy modern vehicle was to develop a network of suppliers that could do all the stuff that we couldn't do. Our background was in restoration and basic maintenance, really a repair shop. And through that process, we started finding local, local people, mostly kind of, essentially cottage industry vendors that were able to work with us, in most cases on a one-off basis, thats small. And through that sort of repair and custom business, we realized that we had the groundwork of a network that would be able to support our manufacturing or production line, our production manufacturing operation. And so over the years through that process, we have honed in on different vendors, we use some more than others than we used to. But we have developed the backbone of the company, which is a network of small hyperlocal job shops that do all the parts that we do locally, and that would be all the chassis bodywork, everything that makes the motorcycle the ride and the feel of the bike. And then we look to external vendors as far away as the other side of the world for some of the specialty parts like engines, brake systems, lighting, suspension, etc.

Hello, this is Brent, he's with Modern machine shop. I'm just giving a tour around. I don't have anything to pick up or drop. So these would be saddlebags battery bikes.

Brent Donaldson: I like your work in the main facility. They're very good.

Janus Supplier: So you got to start working for them?

Brent Donaldson: No, no, I write for a magazine that's been around since 1928. It's called Modern Machine Shop.

Janus Supplier: I see. Yeah. You're gonna do an article for them?

Brent Donaldson: Yes, a story.

Richard Worsham: Mark has been doing stuff for us probably back when we had a 50 CC, little bike in 11 or 12.

Brent Donaldson: How did you guys meet?

Richard Worsham: Glen Coons up there. And Leroy recommended me, he taught Glenn in school. So, Mark has all the saddlebags, battery covers, and the seats for the forefront. They're more of upholstery. So we have a company in St. Louis that specializes in motorcycles. It's so complex, the French seams and we have to sky the leather seams. I think they have much bigger. They do a lot for Harley Davidson. Anything we can, we do right here. Mark has stamps that he can cut the stuff out on a press.

Brent Donaldson: So is this a family business? Your dad does this too?

Janus Supplier: I actually started this myself back in ‘07 as more of a hobby than anything. And then these guys came along and it turned into more than a hobby.

Richard Worsham: You are working in a factory right? How long ago?

Janus Supplier: It's about two years now.

Brent Donaldson: Do you like this better, working for yourself?

Janus Supplier: Yeah.

Richard Worsham: But a lot of your business is harness?

Janus Supplier: Right, harness. And I do quite a bit of stuff for the welding industry, chaps, I really like that. Welding, protection. Like aprons. And I do some stuff for my brother-in-law that makes some cannabis products for a guy in California.

Richard Worsham: It is really high-end stuff. What's the name of that brand?

Janus Supplier: Resistol.

Richard Worsham: So yeah, we're huge fans of Made in America. Although we don't take it to a sort of moral level. Really, for us. It's kind of a pragmatic approach that, especially when we were small, it made way more sense for us to have a vendor down the road, that we could go talk to about a part than to have a, let's say, for example, an Italian vendor that maybe was harder to even have a conversation with because of a language barrier. And then shipping parts was really difficult. So 10 years ago, supply chain was a concern for us. And being able to have a local network of vendors that you have a friendship with, you have a personal relationship with just shortens those chains down to just right around the corner. It is it has been for us a pragmatic decision, but one that we can feel good about when we get to sleep at night as well, that we're supporting the local economy and we're really more efficient. Rather than being about Made in America, we're about made in Elkhart County. Yeah, so I talked a little bit about how we were essentially a custom shop and we found, you know, a couple of vendors and we started off with really the first vendor we started with was a powder coater Amish fella, Ernie, who would powder coat our kind of custom chassis and parts. And through him is really kind of was kind of the starting point for developing a network. I don't know what would have happened if it had been a different person. It's kind of interesting to think about that. But it was an Amish guy and when we asked him, Hey, we're looking for somebody who could make a chassis, for example. And he's like, Oh, well, there's a Leroy up the road. And he's made funny car chassis. This is an Amish guy, oddly enough, and he's also done bicycle frames. And immediately we're like, funny car chassis, bicycle frames, okay, this could work. And so we went and talked to him. And he's like, Yeah, I'm more than happy to humor you basically, I don't know where this is gonna go. But he had the time for two kind of green-looking English guys, as the Amish call us, to basically set up shop in the back of his fabrication shop. And we built up chassis from scratch. And that kind of set the standard for how we would initially bring out the bikes, we would develop the first one, helped them build the tooling, and then pass off the production to them. And then next up we need to make a seat for this bike. Hey Leroy do you know anybody who does leather work? And he goes, Well, I know Mark right down the road. And lo and behold, Mark is still the guy who makes all of our 250 seats, all of our saddlebags, and wax Canvas goods. And then when we need some polishing done, Mark says, Oh, I got my brother. So basically, it's just this network. And because of the word-of-mouth nature of it, it's in a pretty compact, geographic distribution. we joke, it's within a day's buggy ride. That's kind of been how we've developed it. And then, of course, that doesn't work for everything. There are specialty operations, our wiring harnesses are no longer made in Plymouth, Indiana, which is half an hour from here. We get them made in Iowa by a special wiring harness manufacturer, but for the most part, it just makes sense to have it made right down the road.

Like, all these guys have side hustles Mark's business started as this, they order a bunch of fruit from Florida. And this is an honor system. Anybody can ride their buggy here It's all Amish. I mean I bought for deer, sometimes you can decide whether you want to check the charcoal, this is great charcoal, by the way, that side which is polishing. So he set this up entirely as a result of our workshop with him. It was right, hey, we need somebody to do this. I've been looking for something to do. So he's, I think at this point is mostly doing. I'm actually a little confused on what he does because I knew I've seen some tents in here. So maybe they split up the work. But basically, here's my costs. There's an order tag, you can see literally talking about the brush, polish. So these are all they will be crushed or polished when they're ready right here for me.

I think that when we started the idea of having a brand, which was the idea of a production vehicle brand, like I said, from the get-go. There was some idea of it being locally made, I think that was kind of baked into that maybe on some level. Even as a kid, I had a vehicle brand name that I designed cars around and I would imagine that that would be something like Ferrari, you know where it's made in this specific town in Italy. And so that was something in my head, but never in my wildest dreams would I imagine that it would be the sort of bearded Amish guys that, all of the parts that they make for us, they're not running off the grid. There's all that power is coming off of a diesel generator, which is just wild. These guys were already there doing what they do and it made sense for us. I guess it was a good match. Because as we develop the brand, it's helped us kind of like niche down in the sense that our bikes are relatively low technology. It's not a coincidence that they're also made with very low technology tools, most of the equipment that they're using out there dates from World War Two, probably. And so it is something that sort of it augments itself as it grows. And I think that the same thing is true in reverse. And I'm not saying that we're gonna convert them to using cell phones. But it's been really interesting to watch these brands, now these companies that we work with, develop themselves into brands in some cases like they have a brush hog business or something that they've developed on the side and I don't know if they would be producing things like that if they hadn't been a part of what we're doing as well. So yeah, it's kind of a symbiotic relationship. I guess from the get go. It's been it's always been a challenge to find a motor for our bikes that fits what we're trying to do. The typical engine when you think of a motorcycle made in the United States is a big old honkin, V Twin made by either Harley Davidson or Indian or s&s cycle. And believe me, we've looked at doing that or chopping up S&S in half and making a kind of a beautiful single, but really it didn't fit with what we're trying to do. What we're trying to do is inspired by how we got started. Our start was in vintage, small displacement, often 50 cc mopeds. I didn't grow up with motorcycles, I grew up with an old Vesper and a vintage mopeds, single cylinders. And that's where I fell in love with the experience of riding this super pared down simple thing. And especially, it's something that was related to doing your own maintenance, like that was a big part of my love of bikes. So when we wanted to select a motor, we automatically weren't looking at the states, because there's nothing like that made here. And so where do we go, we went to kind of developing markets where there are these amazing engines that are absolutely indestructible, they were actually developed to be indestructible, and are now being manufactured by old OEMs for Honda in mainland China. So the 250 engine, which is really the backbone of what we've built so far, is a 229 CC, air cooled. push rod, super overhead valve, like extremely simple engine, that was developed by Honda in the '70s, to be indestructible, to be bulletproof. And so it perfectly fits what we're trying to do. Because we don't have dealers, we don't have a maintenance network around the country. And meanwhile, we're trying to inspire people to have this intimate connection with their vehicle where they can do their own maintenance. So it all kind of ties together to create this match with this small displacement, simple engine, which just happens to also not be made in the States. We tell everybody, hey, if you know of a small, simple single cylinder carbureted engine made in the States, you let us know, we'll explore it. But we're also just not interested in like, a design that's been out for two years. Part of having a reliable engine is having one that with parts availability, like these engines they've been making parts for this thing for three decades, four decades. So that was a big part of it. And yes, we do get lots of questions from people like how in the world do you expect me to shell over a handmade American price, and then it has this Chinese motor in it? And it's been a journey to explain the fact that this is actually the perfect motor, it's the most reliable engine, it's far more reliable. I won't name any names, but it will, it will take you as I can tell you from experience from coast to coast without any issues. And it's something that you can repair yourself, we have the longest motorcycle industry warranty, four-year warranty on the 250 fender to fender. And we don't lose money on it. Let's just say that it's a very reliable little motor. If you use it for the use, it's for which is it's certainly not a highway bike that they get on that you're doing 80 miles an hour on. The same thing holds true of our 450 which is another kind of an X Honda design based on the XR 400 manufactured in China for an Italian company. And again, it's a platform that we were looking for with about twice the horsepower of the 250. But we wanted fuel injection, we wanted all these single cylinder still. And lo and behold, here's the perfect fit, because you're not going to find that in any other stateside manufacturer. Certainly with it with that, with that level of reliability that we're looking for.

Yeah, yeah, exactly. So the same exact argument is behind all our selection of other specialty components. So by specialty, we mean things that like a shock absorber is not something that, I mean we've spent 10 years perfecting how to make a chassis and a motorcycle that works and assembles well in production. But developing a suspension system, you could spend 60 years doing that and that's exactly what our suspension system supplier has done. It's called Ikon suspension which if you mix those letters around, it's Koni. So very famous history. When Koni stopped making motorcycle shocks, Icon purchase them and they're made in Australia and they're the preeminent traditional shock absorber. And by that I mean coil over paired rear suspension shock, real beautiful looking shock absorbers that fit exactly what we're trying to do. So that was the logical choice for us to go to them. Another example would be lighting. So like D O T lighting, good luck finding any of that stateside these days, I hope that changes. But we go to a company in Taiwan, where all the big US motorcycle manufacturers also get their lighting. And similarly true of other parts on the bike that are specialty items that take a long time to develop and involve a lot of specialty stuff. And so in that part, we actually feel like we're participating in a long tradition in motorcycles and in cars of like Bruff superior and early Vincent's, they focused on the chassis, and they would source the specialty items from the experts. With certain people, the flag waving, which I'm I mean, I'll wave the flag, and I certainly am proud to be able to do what we do. But at a certain point, it becomes a kind of a moral imperative. And I mean, at a certain point, you're not going to really convince some people. So it's kind of like maybe we're not worth picking that fight. Other people, I think, are very aware, it's becoming much more clear to folks that there's so much of all the things that we use that are made overseas. And so there's an increasing understanding of that. But for us, really, it's the main argument that we give is, we're looking for the best tool for the job. Not that it has the sort of logo on it that makes it approved or not, whether that logo is a brand or a country, we're trying to find the right tool for the job. I always tell people, if I had developed this motor, and I spent the time and money to do that, I don't think you'd want to rely on that, within the first 10 years, at least. Well, let's leave this to the people that really know how to do this, and have this long track record of being able to do it. And then kind of gradually maybe, yeah, okay, I love being able to bring country and start somewhere, the RV industry, love it or hate it. I think it's great, I'm a big supporter, but it's kind of the Wild West. And it fosters these differences even within the county, these different cultures and different kinds of communities of how things are made between even between one brand between one plant and the next. And lots of leaves, small shops, making small runs of parts, for even if it's for a big brand, a lot of times they'll have multiple shops doing the same part for them. And there's a lot of room for small machine shops to get started. And those small machine shops are more than happy to take an order of 25 or that powder coat shop or whatever it is that you need. The only time we've run into problems with our minimum order quantity being too small is when we go overseas. And that's really what's kept us from going overseas. If I were to try and get frames made in China or Taiwan, I have to order many, many, many, many more times than I would ever be able to afford and so as weird as it sounds, the fact that we're able to do this here is why it worked at all. It's just been a necessity that we focus on the highest levels of quality, detail, and handwork and then demand a high price for our bikes they're not there. I don't know if I put my reputation on being the most expensive 250 in the world but we might be.

Do you have actual pickups here is this just part of the tour?

Brent Donaldson: Do you have actual pickups here is this just part of the tour?

Richard Worsham: I have a check to drop off so we'll see. This is Brent from Modern Machine Shop. He's been riding along.

Brent Donaldson: How many employees do you have?

Janus Supplier: Me, my wife who is in the office and another guy. I bought brand new March of 1990 33 years ago, and we still run it.

Richard Worsham: So, Brent got to ride along this morning on what we call the milk run, which is a central part of what we do and a central part of how we're able to work with all these local vendors, especially if they are Amish and don't drive. So the milkman is a big black van that we drive around the county, picking up and dropping off parts as the simple version of it. When you dig down a little bit, it's a pretty complicated system. Every day, there is at least one milk run, we have a guy whose entire job is he's the milkman. And he'll start off here in the morning, just like we did this morning 9:30, he picks up any parts that are here at the shop. And so to run through those, those would be parts that have arrived at our HQ which is mostly assembly, and then that need some other process to happen to them before they come back here. So a great example of that would be polishing, or powder coating, or any kind of finishing process, in some cases sandblasting if we're actually making that part. First of all, we'll pick up let's say, a powder-coated part that needs to be powder coated or sandblasted. We'll get in the van. And then the first stop will be our fabrication shop, which is the most recent addition to our Janus real estate. It's old manufacturing, building about three miles, two miles south of our downtown headquarters. And in that building, when we launched our 450 model about two years ago, we set up a fabrication shop. And so that was kind of the first step toward bringing some more of our manufacturing in-house. All 450 chassis components are fabricated there. We'll pick up some finished chassis, put them in the van we also at that location manufacture fenders and there are beautiful fenders that are pretty much ready for paint. By the time they're done there. We'll pick those up. And then we'll head out into what we affectionately call the inner world. The Amish call us the outer world so we flip it around a little bit. So it's not a spiritual state. It's just a part of the county. But we drive out there and the next stop will be our exhaust manufacturer right on the outskirts of Goshen. Joe works in his barn, welds up all of our stainless steel exhausts will pick up or drop off tags that show that we need more exhausts. And then we'll take them to the next step which will be our laser cutter. And that's where all of not only the sheet metal parts, lots of sheet metal parts go into a Janus bike, but also the tube parts which are also laser cut for our 450 components, oftentimes, like this morning will pick up a pallet of parts just for Coons, they're not even going to a Janus, they're just it we help out our fabrication shop. Next up is our fabrication shop, where we'll drop off those parts, pick up any 250 components that are ready to go which would be frames, fuel tanks, and any number of other small items that they make. And we'll proceed but a mile and a half down the road to Mark's the harness maker. Pick up some leather goods. And then the next step will be polishing. So we will either pick up or drop off parts that need to be polished which would be handlebars, or exhausts or some deluxe fuel tanks. And then head across the street to his brother, Sam, and drop off any 450 or 250 parts that are ready to be sandblasted and pick up any parts that are sandblasted and that are ready for powder coat. I should mention that a lot of these parts like we headed out this morning. They're already in the system. So you're taking apart, you may not have it when you leave but you're taking it from one stop to the next. And it's like a big machine kind of thing. Just circulating these parts gradually and sometimes it takes two weeks for that, for one part to make its way all the way around the county. But we're doing this because we're doing it every day. We're constantly moving those parts from one spot to the next. After sandblast, we will head down the road a little further to our powder coater where we actually powder coat all of our frames and bodywork on the bikes will drop off anything that's been freshly sandblasted, or that is ready for powder coat and pick up any parts that are already painted and ready to go back to the shop. The next stop will be our machinist, Don, and he's about five miles south of Goshen. Fantastic little shop where it's specializing in really high precision, smaller pieces, axles, fuel caps, carburetor needles, a wide range of parts, he really specializes in Swiss lathes. So you can do small delicate parts. And to a really high level of fit and finish. And then it's back to HQ to unload all the parts and have them ready for the assembly team to start production on a bike. Anything coming from overseas is open to the potential of a delay, we are ordering some parts up to a year or more in advance. So you have a massive amount of inventory held up and capital held up that way. Whereas if you're ordering 25 of something from a local vendor, you can go pick it up the next day, if you need to, you can say, Hey, Don, is there any way we can move this up a little bit? And he can do that? And yeah, if we could have every single part made locally, absolutely. With our business model, that's the direction we're going. I mean, it is challenging to work with people who don't use the internet. I have been accused of being a Luddite. And I don't shy away from that, I think it's great. But sometimes the way things happen most people enter their email. And none of our Amish vendors use email, our fax machine gets a lot of use, though. So we do a lot of faxing. And sometimes when that gets printed off the fax machine, the print loses some legibility. So we have issues with that. Sometimes it's just easier to hand it off manually. Other times if somebody isn't using cam, their hand programming, something things can be missed that way, or it so it really it makes us have to have our prints, really in order, because a paper print is still to this day. If it's done well, it carries all the information and you can hold someone to a standard. That said, even the best print sometimes with our overseas vendors, they'll just miss something. And then something I just ran into this week is we've already made all of them. And because it's overseas, and it's large, we are required to make larger orders, like we just talked about, you have to and 50 of something that isn't the way you want it. And there's not much you can do. So. But for the most part, it really hasn't. It's not an insurmountable thing. It's like we have to adapt to the differences in technology or how people do things, but it's nowhere near as challenging as even the highest technology supplier being far, far away. I guess one thing I would one point I'd make on in terms of people being on the other side of the world is sometimes I don't know if it's even bad, like our suspension supplier, we've had the best relationship, but I guess it goes back to that relationship thing. Like I've met him numerous times. He's in Australia, he's been on my podcast, I consider him a friend. And we just, we really don't have any issues. He knows what we want. And so if you can create this kind of relationship, which it's hard to do over long distances, it can create a really great business model. But for the most part, there's nothing that beats having somebody down at the end of the road that you can talk to.

When you say you don't want to treat them as others, but that is how they treat themselves. They really do set themselves apart from what would they call us English. They call us the outer world. And we call them the inner world and we buy into it, but we also realize that they're more than willing to talk about what they do. When I first worked on that first Amish vendor, I was like, just don't talk about technology or anything and then I realized they will make the biggest jokes about it. You can rip them for having a telephone and they think it's hilarious. They have a fantastically optimistic sense of humor and my experience with working with them has been one of complete admiration. It seems like they're they are not a victim to the cynicism that that so much of modernity has kind of fallen into. I always leave with a huge smile on my face after talking to Amish guys and the women that work in the fabrication shop. It's been an amazingly positive experience that I have heard of people making fast personal friendships with Amish, but they really do kind of hold of themselves. It's a very stoic kind of a relationship. As it matures, it gets more real, but it's been, it's been incredibly positive for us. And it's something there, you can absolutely rely on their word and their honesty and standing behind their product. So it's awesome.

Brent Donaldson: What would you say between your local vendor network and the quality of the bikes?

Richard Worsham: I would just say that if you're interested in a machine that really gets to the human experience, the reason we got on motorcycles in the first place. And our belief is that things that are made by hand, are intrinsically and locally they have a quality that makes them more valuable to us. And that is more likely to last over time. It's a concentration of human effort, that even if even a part that's made by a machine that's identical to a part of this made by hand with care, there is a difference. I don't know if we can define it scientifically. But that's what we're kind of focusing on. And if you're interested in that kind of thing. Check us out. Janusmotorcycles.com.

Brent Donaldson: Made in the USA is a production of Modern Machine Shop and published by Gardner Business Media. The series is written and produced by me and by Peter Zelinski. I mix and edit the show. Pete also appears in our sister podcast all about 3d printing or additive manufacturing. Find AM radio wherever you get your podcasts, our outro theme song is by The Hiders if you enjoyed this episode, please do leave a nice review. You can just tap on the fifth star that is just fine and very much appreciated. If you have comments or questions, email us at madeintheUSA@Gardnerweb.com Or check us out at mmsonline.com/madeintheUSApodcast.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)