Interface Streamlines Robotic Removal of Molded Parts

IMTS22: The SPI-67 is an electrical interface from Yaskawa designed to maximize uptime and throughput of GP-series and HC-series robots.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

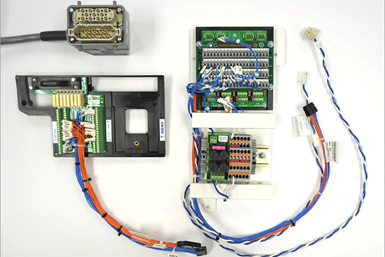

Featured Content

View MoreThe SPI-67 electrical interface from Yaskawa America Inc. accommodates application requirements for the robotic removal of molded parts from horizontal injection molding machines (IMMs). Installed in the YRC1000 controller, this hardware and software solution maximizes uptime and throughput for GP-series and HC-series robots, according to Yaskawa.

Conforming with international standards and safety regulations, SPI-67 is EuroMap 67-compliant and adheres to the Society of the Plastics Industry Inc. (SPI) electrical interface guidelines.

Interface communication transmits standard handshaking signals, such as door status, robot operating and ejector position. A 50-pin interface connection acts as a physical link between the robot and the IMM. Dual-channel/redundant safety signals enable direct connection to the IMM.

Mounted within the YRC1000 controller, there is no need for an additional cabinet. A door-mounted safety and power interface provides the needed safety I/O and includes two unused, dual-channel safety contacts that can be used for interfacing with safety input devices or paired with the Functional Safety Unit (FSU) output functions to obtain dual-channel, dry contact safety-rated outputs.

Direct Connect I/O cards enable convenient access to the robot’s native 40 inputs and 40 outputs while adding valuable relay outputs. NPN and PNP versions are available.

Related Content

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

.jpg;maxWidth=300;quality=90)