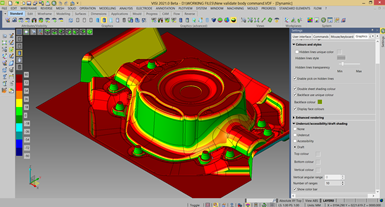

Hexagon VISI 2021 Improves CAD Analysis

Hexagon's VISI 2021 includes new analysis-shading modes to improve CAD analysis.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

VISI 2021, the mold and die CAD/CAM software from Hexagon, includes new and enhanced functionality features, including new analysis-shading modes to improve CAD analysis. Draft Analysis joins the existing Undercut and Accessibility shadings, performing on-the-fly analysis of draft angles. This extends the undercut mode’s technique to more ranges, the company says. Users can change the colors and angular value of each range by clicking on the colors or numeric labels on the graphics toolbar.

Repair functions used in the Repair Invalid Faces of Bodies command are now integrated in the Validate command. Auto Zoom also enables users to zoom in on potential issues.

Developments to the CAD Reverse module are also said to improve the Reverse and Casting processes. The shaded view is designed to provide faster and more accurate feedback to the scanning operation, and new features increase the probing solution. “Leapfrog” management updates in Casting improve the laser tracker’s scanning accuracy for both small and large parts, according to the company. Reverse projects can now benefit from faster and more precise surface creation.

Point Scanning enables operators to view the shaded point cloud during the scanning operation, giving them an immediate report on scanning accuracy and potential missing areas.

A new option automatically creates a mesh as a scanning result, suitable for when results need to be quicker but not as detailed.

Improvements to probing during the Reverse process are designed to detect the correct diameter of the part in relation to the position of the probed points. A new Circle/Slot probing feature for probing and designing a circle or slot gives operators several options to ensure the probed element is the correct size and in the correct position. This prevents the need to create a mesh first, instead creating relative surfaces and saving time where curves can identify the shape.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.