HCL Technologies Enhances 3D CAD Data Viewing Software

Glovius 6.0’s engine is designed to significantly improve file open and rendering performance, which reportedly results in improved visualization and responsiveness. The latest release enables users to measure STL, CGR and other graphics file formats.

Share

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

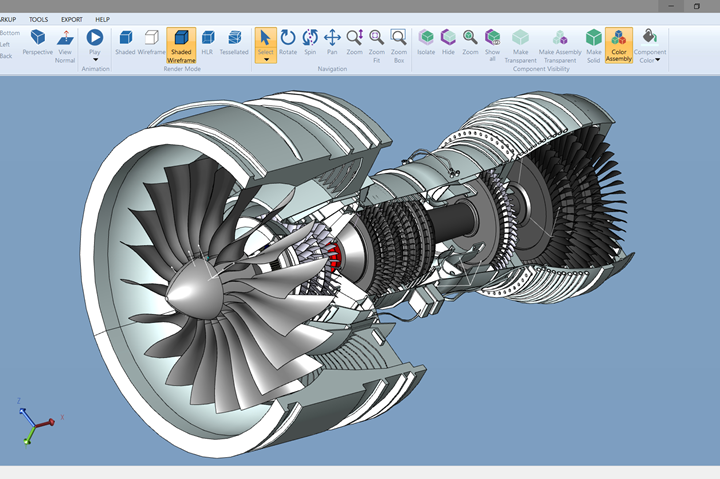

View MoreHCL Technologies announced the release of HCL Glovius 6.0, which reportedly features enhanced functionalities for easy consumption and viewing of product design data. Glovius is a multi-platform visualization solution that enables access to 3D CAD data on Windows, Cloud, iOS and Android apps.

According to HCL, Glovius supports all popular CAD formats, including Catia, NX, Creo and Pro/Engineer, Solidworks, SolidEdge, Autodesk Inventor, Step, IGES and JT. Glovius enables users to measure, section, analyze, compare and export 3D CAD data to Step, IGES and other formats. The new rendering engine in Glovius 6.0 is designed to significantly improve file open and rendering performance, which reportedly results in improved visualization and responsiveness. The latest release improves picking and rendering of measurements, enabling users to measure STL, CGR and other graphics file formats. Additionally, Glovius 6.0 features an improved export option with WYSIWYG enhancements, enabling users to export files as image snapshots, PowerPoint, 3DHTML, 3DPDF and Bill of Materials (BoM) for easy sharing and collaboration. Users can also protect IP and product design data by selectively exporting components in an assembly.

Working remotely, teams can seamlessly collaborate across screens with comments, email and markup on the latest 3D product data.

HCL says that Glovius for iOS and Android provides a simple and easy way to view, showcase and collaborate on 3D CAD parts and assemblies on iPhone, iPad and Android devices. With Glovius mobile apps, users can view 3D parts and assemblies from popular CAD formats, analyze CAD components, run reports and collaborate with others.

Related Content

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.png;maxWidth=150)