Glebar's Electrolyte Tank Enhances Grind Management

The tank’s digital ultrasonic sensors connect with an I/O link to the HMI screen, which Glebar claims will enable better grind management, improved grind efficiency and reduced downtime.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

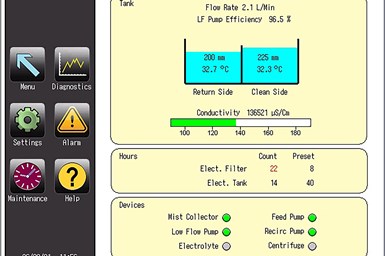

HMI screen displaying electrolyte health and fill level data as recorded by the enhanced sensors in the upgraded tank.

Photo Credit: Glebar

Glebar has developed an enhanced electrolyte tank that features digital ultrasonic sensors. The sensors feed data to connect with an I/O link to the human-machine interface (HMI) screen, which Glebar claims will enable better grind management, improved grind efficiency and reduced downtime. The upgraded tank provides users with a reliable way to check the electrolyte levels of their Tridex Electrochemical Cutoff and Grinding machines without having to do so manually.

Currently, operators monitor float hydrometers and perform visual inspections to measure the electrolyte salt density and fill levels. These are manual and operator-dependent processes that are said to provide an insufficient amount of data to accurately plan for electrolyte change and result in a lower process capability.

In the upgraded tanks, an I/O link switch connects digital ultrasonic sensors to the HMI screen which generates a graphical and numerical display of the electrolyte health and fill levels. This enables operators to make precise adjustments through a simpler and more accurate process. The alerts generated by the HMI enable operators to quickly make changes, which is said to result in less time spent troubleshooting.

Tom Travia, director of electrochemical grinding at Glebar, comments, “The digital ultrasonic sensors upload the electrolyte health data to the HMI screen, saving time and money.”

With the enhanced sensors and detailed display, Glebar says the new electrolyte tanks can reduce unplanned downtime, as well as increase throughput and process capability.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)