Giving Clean a New Meaning: Standard Parts in Hygienic Design

J.W. Winco adds new sealed standard parts made of stainless steel for very high-hygienic requirements.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

At first glance, most standard parts seem far away from actual critical work areas, but airborne spores of microorganisms can spread quickly and far. Since even the slightest weak points can lead to contamination of entire production lines, J.W. Winco develops a complete product family of special standard parts. It combines minimal contamination tendency with optimum cleaning ability. As a result, parts meet the high requirements of the 3-A sanitary standard, the EHEDG and the DGUV test, according to the company.

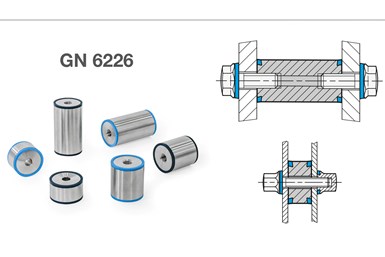

The latest addition to the Hygienic Design product family, the spacers GN 6226 are now offered by J.W. Winco. These standard parts avoid duplicate mounting surfaces, which are problematic and time-consuming in terms of cleaning and sealing. The HD product range continues to grow with new parts joining the existing range of knobs, U-handles, hand levers, indexing plungers, latches, cover sleeves, leveling feet and screws.

In all cases, stainless steel with vibratory finished or polished surfaces is used as the material. The company notes this means that the maximum surface roughness remains below Ra 0.8 μm, so dirt particles cannot settle and can be reliably removed during cleaning.

Another central feature of the J.W. Winco standard parts is the absence of dead space. No substances can accumulate inside the components.

A hygienically safe sealing concept, verified by software simulation, promotes that the FDA-compliant H-NBR or EPDM elastomer seals fit flush everywhere after assembly and fulfill their function over the long term. This reduces the chance of any hygienic problems going unnoticed. J.W. Winco provides detailed information on professional installation and suitable cleaning procedures.

Overall, J.W. Winco says the Hygienic Design standard elements reduce the effort required for cleaning — which can be carried out more efficiently and faster via the “Clean in Place” concept. The bottom line: plant operation becomes more cost-effective over the long term, the company notes.