Concepts NREC Software Facilitates Efficient Machining

The updated Agile Engineering Design System enables engineers to explore some of the cycles that have the potential to reduce carbon emissions in all applications.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

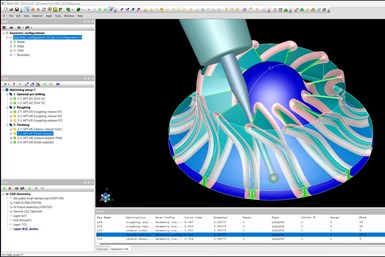

View MoreConcepts NREC has released the latest version of its Agile Engineering Design System, an integrated suite of software modules for computer-aided engineering (CAE) and CAM specialized for turbomachinery.

The 2023.2 release focuses on the needs of designers and manufacturers of turbomachinery in the propulsion, as well as the renewable and alternative energy markets. The new release of CAE enables engineers to explore some of the cycles that have the potential to reduce carbon emissions in all applications, including the use of hydrogen in combustion and fuel cell applications. The new release of the MAX-PAC CAM software pairs with the new version of AxCent for design so that moving from design to production is easier. In addition, the company has added more generic capabilities to MAX-PAC, such as hole drilling to save time by staying within MAX-PAC rather than going out to a general-purpose CAM software.

“Many of our long time customers are using their in-house turbomachinery expertise to move into the new green technologies and our new version of software will help them to make that pivot. In the propulsion area we see that designers of rocket as well as gas turbine engines are pushing us hard to make their jobs easier and we have responded with this new release,” says Peter Weitzman, president of software sales and business development.

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

.png;maxWidth=150)