ANCA's ToolRoom RN34 Software Eases Tool Balancing

ANCA’s ToolRoom RN34 supports ballnose cutting edges, which are suited for the aerospace, die/mold, general machining and power generation industries.

Share

ANCA’s ToolRoom RN34, with support for complex endmill geometries, is designed to improve cutting tool manufacturers’ productivity in the aerospace, die/mold, general machining and power generation industries. The high complexity of endmills designed to minimize quality issues resulting from chatter influenced the development of Tool Balancing in ToolRoom RN34 release. According to the company, direct communication between design and simulation software packages has simplified and eased tool balancing.

While the ability to design and manufacture chatter-avoiding variable helix/lead and pitch pieces, as well as variable helix/lead pieces with angle changes along the flute, are long-standing software offerings, variable helix/pitch introduces uneven weight distribution throughout the tool and requires balancing at higher rpms.

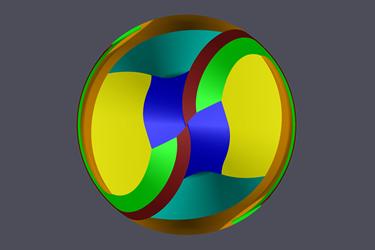

To simplify creation of balanced tools, a graphical drag-and-drop designer cutting edge replaces the constant helix ballnose option. This new ballnose cutting edge, featuring optimized irregular helix curves, becomes available when switching from 2D projections of the cutting edge to 3D projections. These tools are recommended for die mold, power generation and aerospace applications.

Grinding a standard ballnose cutting tool with the correct chisel angle and relief, straightness and ball profile line form is difficult, but ToolRoom RN34 has simplified it by automating the entire process. The end-user only needs to choose the proper chisel style and new cycles will populate the grinding parameters automatically. This enables center cutting of ballnose tools and eliminates wear and tear of the tip section.

Other features within the latest version of ToolRoom RN34 include revamped ToolTypes. These include double-radius endmills, threadmills, lollipop cutters, countersink tools, pocket grinding applications, embedded grinding files, new grinding methods, chipbreaker operations, constant helix fir tree cutters, protection for grinding files, double margin drills, other enhancements in profile software and other ToolTypes.

Related Content

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)