Air Chuck Features Self-Centering Jaws

SMW Autoblok has released a 3+3 air chuck, including features that make it suitable for OCTG pipe threading.

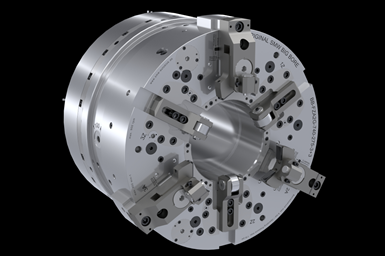

SMW Autoblok’s BB-FZA2G air chuck. Image courtesy of SMW Autoblok.

SMW Autoblok, a company specializing in the design and manufacture of a range of products for the machine tool industry, presents the BB-FZA2G pneumatic 3+3 sequencing air chuck. Featuring an extended stroke clamping range and three self-centering jaws with axial adjustment, this air chuck is said to be well-equipped to handle the harsh demands of the oil and gas industry. The self-centering function of the jaws allows for quick and easy setup of irregularly-shaped pipe for threading and rethreading, and the incorporation of three compensating jaws with a 1.5” clamping stroke eliminates the need to re-shim the part. This is designed to enhance operator safety, as well as overall productivity.

Designed for machining both straight and bent pipe, BB-FZAG is available in 740, 800 and 920 mm sizes to cover a range of pipe diameter sizes, with large through hole sizes of 275, 330 and 390 mm. This unique sequence chuck with a pressure control safety system is designed to increase production output, without re-shimmming of jaws.

Related Content

-

Ceratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.