Liebherr Showcases Gear Technology, Automation at Performance Days

At Performance Days, Liebherr will present new products, host live talks and exchange technology. The event takes place virtually from December 7-9, 2021 and will showcase the company’s gear technology and automation systems.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreLiebherr created its Performance Days event to promote innovation, technology and networking. Liebherr will be using the Tech Arena as a platform to present new products, host live talks and exchange technology. The event, which takes place virtually from December 7-9, 2021, will showcase the company’s gear technology and automation systems.

At Performance Days, the gear technology product area will feature exclusive information about new products and current portfolios. Liebherr will present different solutions of gear hobbing, shaping, skiving, grinding and chamfering, as well as others. It will also feature the newly-developed clamping technology, SECLA. In addition, contact persons will be available to offer advice on all product areas and to develop technical solutions.

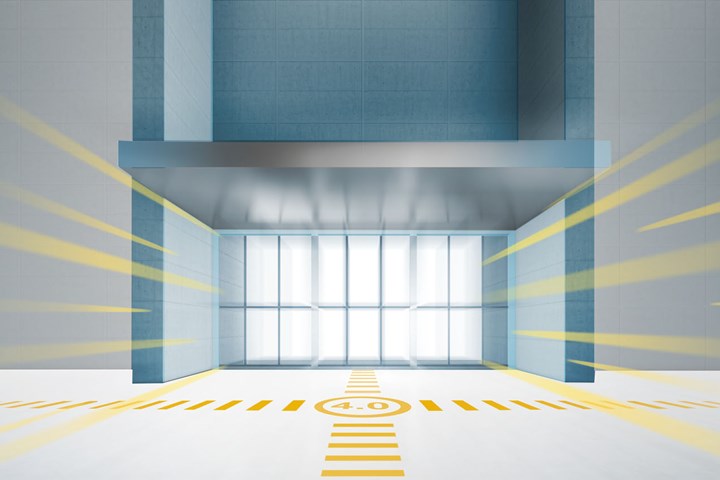

In the area of automation systems, Liebherr plans to introduce an automated concept for the assembly of battery packs. Liebherr also offers custome digitalization solutions for all product areas, including web applications and networking methods. According to the company, the spectrum ranges from simple monitoring applications to far-reaching Industry 4.0 scenarios.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)