Tool Presetter Is an Important Hub for Data-Driven Manufacturing

The presetter/tool measurement machine plays a key role in data-driven manufacturing by serving as single point of contact for the two-way flow of information about cutting tools.

Share

“The tool presetter is one of the most important data hubs in a data-driven manufacturing environment,” Ryan Meleg says. As Global business unit director at Parlec Inc., Mr. Meleg sees how a streamlined flow of data across a computer network that connects all of a shop’s CNC machines and related software applications is essential to the Industry 4.0 concept. More to the point, he emphasizes that the latest tool measuring technology has to play a vital role in this scenario.

“The presetter, which may be better called a tool measuring machine, provides a direct link—a single point of contact—between the tooling database from which part design and CNC programming draw, and the machining process that relies on the tool offset data and tool life information for accurate and precise part production,” he explains. In addition, he says, the presetter/tool measuring machine can check tooling items returning to the tool crib so that the tooling database can be updated with current measurements that reflect detectable edge wear, along with information such as remaining tool life. “This capability closes the gap between the virtual model of the tooling assembly and actual components that do the machining. It also closes the loop between projected tool performance and the actual results from the shop floor,” he says.

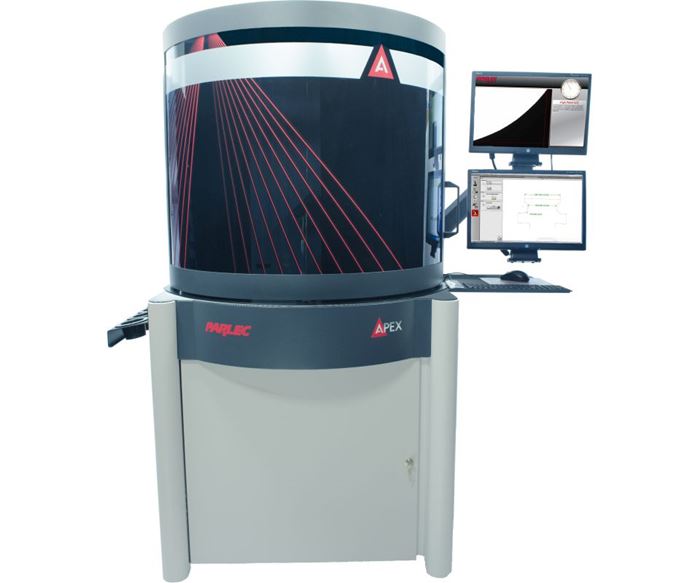

According to Mr. Meleg, two of his company’s most advanced models, the 1850 TMM and the Apex TMM, are particularly well-suited to facilitate data-driven manufacturing. The features and capabilities that account for this suitability deserve a closer look:

- Accuracy and repeatability on the shop floor. Tool measurement has to happen in a shop environment where tools are assembled, inspected and delivered to nearby machining areas. For example, a ductile cast iron structure with hardened and ground ways, sealed bearings and guideways, and a symmetrical design that neutralizes thermal distortion are important construction features of both models.

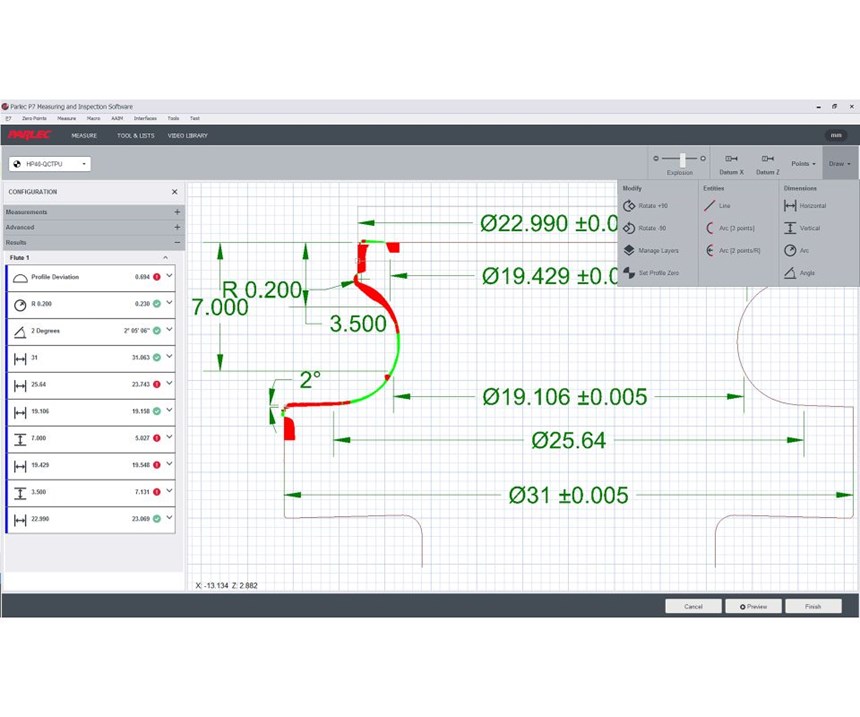

- Digital measurement via a high-resolution video camera. Video sensing technology, combined with an intuitive user interface, enables reliable measurement data to be captured efficiently in the tool assembly area. Options to automate the process for “one-click” operation further streamline this process.

- Provisions for networking and shopfloor connectivity. To act as a data hub, these models are internet- and Ethernet-ready for integration with tool management and manufacturing control systems. Tables of tool-offset data can be conveyed to the machine through a DNC system for downloading or transferred to a radio-frequency identification (RFID) chip in the toolholder for automatic input with a chip reader in the machine tool.

- Options for interfacing with a variety of manufacturing systems. In addition to communicating with the CNC machine tool, the presetter/tool measuring machine can communicate with a tool data management system, making it a gateway to data-driven manufacturing. Options for the 1850 TMM, Apex TMM and other models include several versions of Parlec’s ParleVision tool data management software. The company also partners with TDM Systems, a developer of comprehensive tool data management and communication software.

- Automation for efficiency. The Apex machine, which is designed to measure profiles of form cutting tools and grinding wheels, exemplifies streamlined interaction between the tool measuring machine and the operator in a digital environment. For example, the company’s P7 software enables this machine to import a CAD drawing in the DXF format so it can be used directly to compare, measure and analyze irregular shapes and contours of complex cutting tools. Likewise, a software feature called Echo automatically monitors the operator’s measurement steps when a new tool is measured for the first time. By capturing this process so it can be reproduced, the machine has self-learning capability that increases the throughput of the measurement system.

Characterizing the presetter/tool measuring machine as a hub is not merely employing a figure of speech, Mr. Meleg concludes. Literally, this machine is capable of serving as a one-stop center where all of the information for retrieving, assembling and measuring cutting tools converge. It also enables that data to remain associated with the tool as it travels to and from the machining center. The presetter/tool measuring machine is the essential juncture for the journey of the physical tool and the related packet of data.

Related Content

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More