MMS Blog

Shop Glasses Offer Video and Data Capabilities

Here are some of the applications a manufacturer sees for real-time video streaming from the machine operator's point of view.

Read MoreAutomating Toolpath Optimization

New software features toolpath simulations that run during post processing and automatically updates code, with no editing required by the programmer.

Read MoreEmpowering the American Supply Chain

Major U.S. industries such as automotive will face shortages of parts and the production tooling to make them unless American suppliers step up to increase capacity. An expert in online marketplaces suggests strategies that will bolster the supply chain in this country.

Read MoreVideo: Multi-Axis Quick-Change Workholding

Whether you’re working on complex or relatively straightforward geometries, matching the workholding and tooling to the application maximizes performance.

WatchApril 2014 MBI: Strong Growth Continues

With a reading of 53.6, Gardner’s April metalworking business index showed that the metalworking industry continues to grow at a fast pace.

Read MoreDrilling and Machining Centers Leverage BTA Process

Unisig’s USC-M series drilling and machining centers combine several processes into one machine capable of drilling and machining all four sides of a workpiece, reducing setup time and increasing accuracy for mold manufacturers.

Read More“LaunchPoint” Premieres

A new series from Edge Factor explores how manufacturing professionals were "launched" into their careers.

Read MoreEmag Emphasizes Modular Gear Making

A recent open house event showcased an approach to tailoring a gear production system not through custom engineering, but by assembling the line from complementary standard machines.

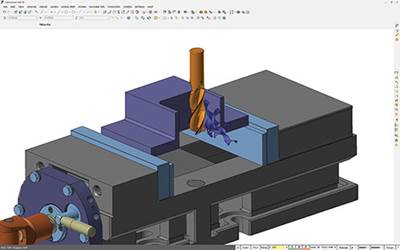

Read MoreDynamic Motion Moves Past Old Boundaries

The Dynamic Motion option in CNC Software’s Mastercam generates tool paths by following an expansive set of rules that are different from those most CAM software has traditionally followed. The motion of the tool is not defined strictly by boundaries of the area to be machined. Instead, the rules take into consideration not only the area from which metal is to be removed, but also the changing condition of the material throughout the various stages of machining.

Read MoreAutomation Moving Forward

There are numerous factors that suggest that machine-tending robots will soon be much more commonplace in U.S. shops.

Read MoreQFS Keeps Its Customers Moving With Integrated CAD/CAM

Quickly updating tool paths to remachine die surfaces enables this shop to provide short runs of prototype formed sheet metal parts. This fast response to engineering changes and design adjustments helps its customers adhere to tightly scheduled vehicle launch programs. QFS relies on integrated CAD and CAM software to make this happen. In this case, the software of choice are PowerShape and PowerMill from Delcam.

Read MoreRefueling Manufacturing Through Storytelling

New media company Edge Factor is partnering with Purdue University and industry leaders to produce educational materials based on episodes of its shows.

Read More