MMS Blog

Are You Using the Right High-Pressure Coolant?

A Texas manufacturer had severe foaming problems with a high-pressure coolant system until it switched to a coolant formulated for use at high psi.

Read MoreMultitasking Turning Centers Equipped with Y Axis

Doosan’s Lynx 220LSY Series is a range of compact and high-speed multitasking turning centers featuring a Y axis.

Read MoreMicromachining Evolution

Challenge Machine continues to add high-speed equipment for the increasing amount of micromachining work it is performing. Here are some lessons it has learned along the way, using tools as small as 0.001 inch in diameter.

Read MoreAutomotive Cylinder Coating for High-Production Applications

Daimler’s Nanoslide cylinder bore coating technology can now be incorporated into an automated process for high-volume production.

Read MoreOne Spindle Housing, Two Dedicated Spindle Motors

This technology combines two separate and dedicated spindle motors in a single spindle housing—one designed to perform high-torque roughing and the other designed for high-speed finishing.

Read MoreCase Study: Chip Conveyor System Saves Floor Space

Hennig explains how its CDF system is used to remove a variety of chips and save space for Advanced Machine and Engineering in this short video case study.

WatchStrongest Year Ever for Robots in North America

North American companies ordered more than 27,000 robots last year, says industry group—a 28-percent increase over the prior year.

Read MoreCylindrical Grinding Technology in Motion

United Grinding's annual Motion Meeting in Thun, Switzerland, highlights the group’s latest developments in cylindrical grinding. News from this year’s event includes the introduction of new models that broaden the range of ID and OD cylindrical grinding in the Studer line.

Read MoreMulti-Axis Workholding System Uses Three-Side Dovetail

The Get-A-Grip pedestal fixture for five-axis workholding uses a triangular clamping geometry for the matching workpiece and clamping dovetails.

Read MoreWire EDM for Jet Engine “Fir Trees”

Advances in wire EDM (electrical discharge machining) technology have made it acceptable for machining critical aerospace parts. It may now become the preferred method for cutting turbine disc “fir trees,” a particularly demanding application that highlights the benefits of this machining process.

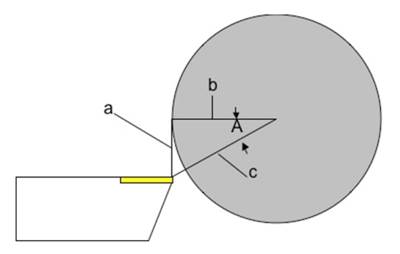

Read MoreMind the Tool Center Height When Turning Small Diameters

Let’s use the Pythagorean Theorem to see how small, turned diameters can vary from nominal when your lathe’s tool center height is off.

Read MoreLarge Machines and Capacity in Renovated Pfronten Facility

DMG MORI hosted its 20th open house earlier this month in Pfronten, Germany. The event featured 76 machine tool exhibits, including four world premieres, and nearly 8,800 attendees had the opportunity to tour the recently renovated and expanded facility to see its latest machine tool technologies. Here are some observations from the event:

Read More