Share

Although Bob Read still shows up for work, the 77-year-old is retired in one sense: He no longer concerns himself with the business side of his manufacturing business. This is possible because of a technology he invented: a porous fixturing material that can apply vacuum gripping force evenly throughout the entire contact area with a 3D surface.

For a little more than six years, this material provided a competitive edge for Technical Tooling, the composite mold and pattern-making shop Mr. Read founded in 2003. However, Mr. Read was happy to let others take on the task of commercializing the material. “He just wanted to use it to help customers, but we knew this needed to be brought to market,” says Zachary Horn, who purchased the business along with Jake Matthaei in 2017.

Welcome! You’ve unlocked premium content.

With no grooves, inlets or other outlets, there are no localized pressure points that can distort, delaminate or otherwise compromise parts.

Patented last year under the name Vacu-Grip, the granular material is now the company’s sole focus. Described by one prospective user as “basically a mixture of kitty litter and glue,” it can be molded into virtually any 3D shape. Once cured, it becomes hard and stiff, resembling the surface of a stone. However, it is also porous. This enables even vacuum pressure to be applied to even the most complex and delicate 3D geometry.

Bob Read invented Vacu-Grip material, which is incorporated in all the fixtures visible here, for Technical Tooling’s own use. Since then, the company has transitioned from mold and pattern-maker to vacuum workholding technology supplier .Photo: Technical Tooling LLC.

The range of applications for the material is broad. One recent project involved mounting a milling machine upside down to cut Inconel parts in an enclosed space. So far, however, the focus has mostly been on machine tool fixtures for trimming composite parts, as well as base structures for composite layup molds (the material’s coefficient of thermal expansion is equivalent to that of Invar). As a workholding material, the co-owners claim it offers the following advantages:

-

A stronger grip. Vacu-Grip fixtures are said to perform better than V-grooved fixtures in shear strength tests, which detect the extent to which side forces push vacuum-mounted parts off a fixture. This enables machining more aggressively (and efficiently) without worrying about even momentarily dislodging parts that, by this point, likely represent a sizeable investment. “It might slip for just a second, but that can be enough for a part to slide 20 thousandths of an inch,” Mr. Horn says, adding that tolerances for trimming operations are usually about ±0.010 inch.

This fixture was built for one of the earliest applications of VacuGrip: trimming wing flap actuator fairings for a jet. Photo: Technical Tooling LLC.

- Full-surface support. A tight match with the contour of the part surface is critical to a stable setup, they say. The company guarantees surface profiles within ±0.003 inch, whether this can be achieved with a pattern or machining the material after curing.

- A gentler touch. Exerting the same level of force at all areas of contact also contributes to setup stability. With no grooves, inlets or other outlets, there are no localized pressure points that can distort, delaminate or

otherwise compromise parts, the co-owners say. There is also less need for tooling pins or other physical fasteners. They add that optional progressive grain structures — that is, more loosely spaced grains at the base of the cured material and tighter spacing at the surface — can be employed to transfer vacuum more quickly for thin or delicate parts. Alternatively, tighter grain options can constrict the vacuum flow.

This fixture uses tooling board as a base for the porous, granular media visible in the gripping areas. Photo: Technical Tooling LLC.

- Easy repair and modification. Once cured, the material is easy to machine. Material also can be added to existing fixtures without affecting function. Prior to the material’s invention, the shop’s composite part trim fixtures were machined from blocks of aluminum or tooling board. In contrast, Vacu-Grip fixtures are constructed by packing the material only where necessary. Channels and gasket-lined grooves to carry the vacuum are also unnecessary.

- Scalability. Rather than being machined away, the underlying “shell,” of a fixture, which can be constructed from a range of materials, often remains mostly intact. Some fixtures require only a few strategically placed pockets to hold the malleable material. This means less material is wasted during production, and larger fixtures are more feasible. “We win a lot of bids because building the tool is much simpler,” Mr. Horn says.

Constructed of tooling board, this vacuum fixture incorporates machined holes and channels to target gripping force. Vacu-Grip does not require this machining.

- Fast changeover. Base fixtures divided into side-walled zones enable indexing and changing individual fixtures in seconds without re-locating for the new setup. In contrast, tooling board constructions might require the use of wrenches, clamps or other devices that could distort the fixture.

The Next Phase

For now, Technical Tooling manufactures all Vacu-Grip fixtures and composite layup mold bases at its Seattle-area facility from submitted customer CAD designs. However, the eventual plan is to transition from providing the fixtures themselves to supplying the raw material for users to build (and to modify and repair) their own vacuum workholding.

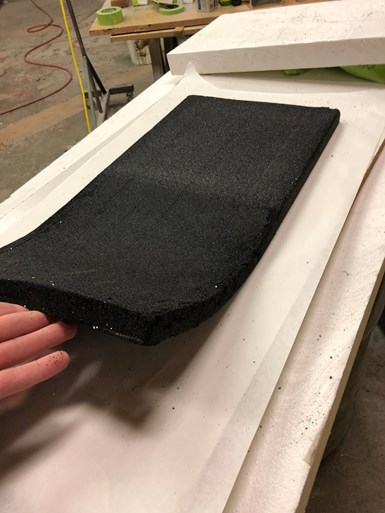

Base material for fixtures is produced in two forms. One is a pliable sheet that can be draped over patterns to achieve near-net-shapes. Other applications are better suited for a version that can be scraped out of a pail and deposited by hand. Curing takes 12 to 24 hours.

Porous and rigid when cured, the material can be applied as sheets like this or pasted directly to underlying fixture bases. Repair and modification involves removing material around the damage, applying new material with a bonding agent and finish-machining the surface. Photo: Technical Tooling LLC.

However, the material will not be available in these raw forms anytime this year, or even next, Mr. Horn and Mr. Matthaei say. This is a long-term goal. Even prior to Technical Tooling investing in the necessary capacity (or becoming able to invest in the necessary capacity), the co-owners say the industry must be educated. “At first glance, this stuff could be anything, and a lot of people assume it’s a kind of tooling board or foam with some give to it,” Mr. Matthaei says. “They don’t realize that it’s very hard and durable.”

The company also will have to grow to the point where it is feasible to make the kinds of investments required to produce Vacu-Grip on a larger scale. “It’s going to take a lot of time to get the necessary equipment and storage facilities, to handle the logistics — we need to walk before we run,” Mr. Horn says. “Right now we’re focused on filling orders, keeping our machines running, buying equipment, and looking at facility upgrades and potential moves.”

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreNavigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreRead Next

Fixturing for Five-Axis CNCs

For some high-batch-size jobs and/or very complex parts, custom fixtures designed and manufactured in house enable Powill Manufacturing and Engineering to get the most out of its five-axis machining capability.

Read MoreCable-Free Tombstones Bring New Life to HMC Operations

Programmable rotary units built into a double-sided tombstone extend unattended operation and add flexibility to palletized machining cells.

Read MoreMagnetic Workholding for Production Parts

The use of magnets for workholding has grown well beyond its traditional role for flat plate materials. Control of magnetic flux is now precise enough to securely hold a much wider array of workpiece configurations.

Read More

.jpg;maxWidth=300;quality=90)