Universal Workholding Solution Grips Challenging Parts

IMTS22: Norgren Workholding’s Adaptix can be quickly set up and grip unique parts for high mix, low volume orders.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

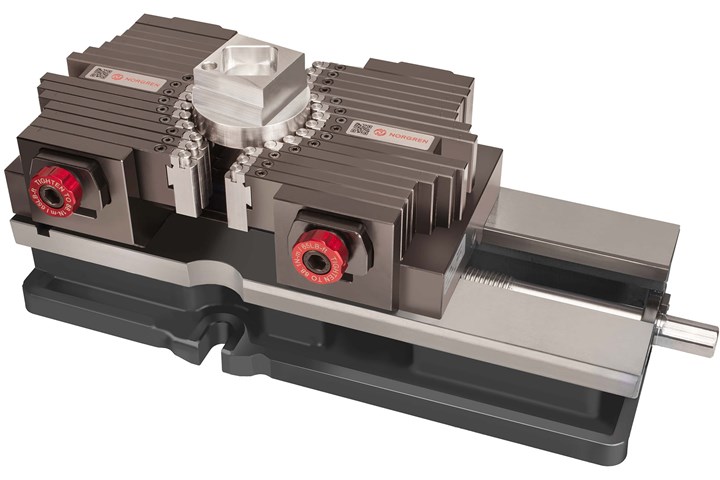

Norgren Workholding demonstrates Adaptix, its unique universal workholding solution, which the company says can rapidly adjust to powerfully grip challenging workpieces. Adaptix’s innovative technology is said to ensure repeatability and precision are maintained throughout the machining process, resulting in more uptime and faster changeovers. Unique shapes can be quickly set up and held for high mix, low volume orders. Its ease of configuration and interchangeable pin tips mean machine operators can reduce set up and changeover times and associated labor costs.

Visitors to the Norgren Workholding’s booth can see the wide range of supporting system components such as tips and studs, which enable the product to adapt clamping forces and grip dependent on the material, as well as see Adaptix in action. Norgren’s team of application engineers will be on-hand to demonstrate Adaptix and to answer technical questions.

Related Content

-

FANUC Details Robotic Vision, ROBODRILLS and More at IMTS 2024

FANUC’s IMTS 2024 booth includes real-time demonstrations that show the abilities of its equipment, including robots, controllers and machine tools.

-

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

-

Trak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.