Two New CAM Features Deliver Real World Savings

Many operations throughout the world are seeking to lower production costs and raise flowthrough. ComputerAided Manufacturing (CAM) offers a means to increase productivity and, as a result, improve customer service and delivery as well. Two manufacturers, an original equipment manufacturer (OEM) in Texas and one in Kansas, are among those trying to maximize their productivity.

Share

Many operations throughout the world are seeking to lower production costs and raise flowthrough. ComputerAided Manufacturing (CAM) offers a means to increase productivity and, as a result, improve customer service and delivery as well. Two manufacturers, an original equipment manufacturer (OEM) in Texas and one in Kansas, are among those trying to maximize their productivity. Both evaluated a number of CAM software packages to be integrated with their new lasers, Bystronics and Trumpf, respectively. Both wanted more capabilities than typical machinetool packages offered: a high degree of automation that would deliver significant savings in material and production time.

Although the goals for the software were similar, overall production strategies and the operation of the software were very different. The Kansas OEM employs a traditional scheduled production strategy. All orders are entered into the MRP system and then downloaded in large quantities (or batches) covering the full range of materials and all types of parts at routine intervals. Multiple part nests are built simultaneously from the demand created by the MRP system and then automatically cued for the machine tool operator to produce. No programmer intervention is required.

The Texas OEM, in contrast, uses a demand-pull process in which dynamic nests are created by the machine tool operator on the floor one at a time, or JIT (just in time). Geometries are designed, programmed and then libraried for nesting as needed automatically. Realtime sales information automatically creates the demand pool for orders just before the creation of each nest. The advantage of this approach is that any rework requirement can be met on the next machine cycle. In addition, if multiple machines are using this JIT nesting, they will be dynamically balanced so each machine will always be working on the next most important parts. Thus, in addition to more efficiency, both companies also needed solutions that could be applied within the parameters of their overall manufacturing systems. Both decided on the Optilaser from Optimation (Independence, Missouri).

This fabrication laser has advanced software features to enhance efficiencies throughout the operation. Two of Optimation's new developments are automatic unattended common cut with safety overcut and collision avoidance.

At the Kansas operation, two primary benefits from nesting with common cut capability are readily available. The first is in scrap reduction: the company has netted $80,000 in material (stainless) savings in the first year of usage alone. Second, the cycle time has decreased because of fewer collisions and subsequent machine shut downs. In fact, it's estimated that this feature reduces cut time by 20 percent or more.

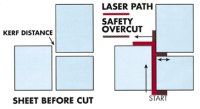

Common cut shortens cycle time by reducing the overall linear distance the laser head travels. Figure 1 illustrates how common cut works.

The nest operator can control which parts are acceptable for common cut in the preprogrammed inputs in the CAD software. Optilaser's nesting module then automatically compares part entities to find intelligent common cutting opportunities— based on arcs or rectangles, unlike some packages which common cut on tangents or points.

The parts are automatically placed together on the nest to form a common cutting edge (including required kerf allowance). The safety overcut feature within the common cut process then directs the laser head to extend the laser path along the common cut edge, as if beginning the next part. This prevents the laser head from returning to the freed part and thus avoids collisions and shutdowns.

The Texas OEM had an even greater return. Because the majority of parts are rectangular, nesting efficiencies are in the 90 percentplus range, virtually eliminating scrap. In addition, because each part shares at least one common edge—and some share as many as four—the total liner distance the laser head moves is greatly reduced. Common cutting has decreased cutting time by at least a third (and sometimes up to half) for this manufacturer, thereby adding even more responsiveness to its JIT philosophy.

As Figure 2 illustrates, the tool path is directed so the laser head avoids all freed parts and other internal cutouts. This is accomplished by working from the innermost cuts toward the skeleton. By eliminating the slow, Zaxis motion, this process enables the laser head to rapid or reposition to the next tool path more quickly. Not only is processing time increased, but the potential costs of damage to a laser head or lost productivity due to shut downs are avoided.

Related Content

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)