Top Shops 2012: Hoyt USA

Lean manufacturing has enabled this company to become more efficient at producing its advanced bows.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreApplying Lean Leads to Success

Company Description

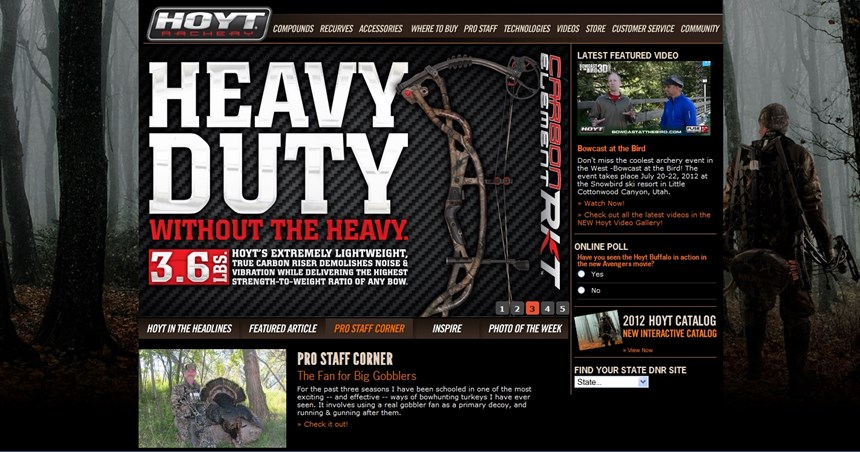

Archery is more than a job at Hoyt: It’s a way of life that drives the company to build the best bows it can. Hoyt is home to a family of like-minded bow fanatics driven to produce what it feels is the highest quality, best-shooting and most trust-worthy bows on the market.

End Markets Served

- Hunting Archery

- Target/Field Archery

- Olympic Archery

Workpiece Materials Commonly Machined

- Aluminum 6061 T6

Contact Information

Hoyt USA

593 Wright Brothers Drive

Salt Lake City, Utah 84116

Phone: 801-363-2990

Fax: 801-537-1470

Related Content

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreJob Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More2024 Top Shops Honorees Announced

Modern Machine Shop Recognizes Excellence in Manufacturing with Annual Award

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)