Tool Storage System Standardizes Setup

Faced with time-consuming setups and tool handling, hydraulic manifold manufacturer Apollo Machinery set out to develop its own compact tool storage and tracking system. In the process, the shop not only increased its own efficiency, but also developed a product that it says could set a standard for CNC machine setup.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreWhen problems arise, shops often turn to trusted suppliers to obtain the latest and greatest in automation equipment, cutting tools, machine components or other technological remedies. Sometimes, however, that dream piece of equipment needed for a given manufacturer’s particular situation simply isn’t readily available or hasn’t yet been developed. In that case, a forward-thinking shop can use its own ingenuity and in-house capabilities to create a solution on its own.

Apollo Machinery in Delta, British Columbia, is one such manufacturer. With floor space at a premium and lengthy setups cutting into production time, the shop sought to obtain a compact CNC tool storage system with software that could upload offsets to its machines and track tool locations and consumables. After determining that no such storage or software systems in the market could meet its needs, Apollo set out to design one for itself. The end result not only reduced setup time, but also enabled the shop to move beyond its core business of manufacturing hydraulic manifolds and market a stand-alone product of its own design.

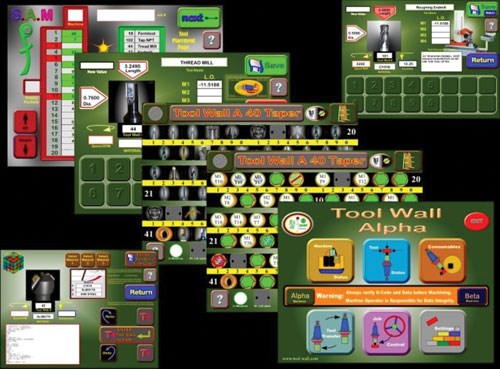

Developed and manufactured by Apollo and available through its Web site at www.tool-wall.com, Tool Wall is the brainchild of Peter Faust, company owner and president. The system consists of two primary components: a vertically oriented storage wall with perpendicular tool receptacles and tool management software that works in conjunction with an external presetter. The core of the system, the storage wall itself, is available in two versions: basic and dual. The basic version can accommodate either 160 40-taper tools or 60 50-taper tools, while the dual version can accommodate either 320 40-taper or 120 50-taper tools. Both models have compact footprints—the basic measures 34 × 40 × 69 inches, and the dual measures 48 × 40 × 69 inches.

"We have about 400 tools in one of our bays, and if we used carts, we’d be tripping over them," says Oliver Brett, general manager. "We designed the wall so that the tools would be visible, but also so that the footprint would be minimal. Most systems store tools vertically, but ours stores the tools horizontally, which allows you to layer the tools on top of each other while still being able to see and access them."

The wall’s patented receptacles hold the tools in place by engaging the retention studs on their holders. Thus, all tools stored in the Tool Wall must be installed in 40- or 50-taper holders with retention studs. Mr. Brett says this "one tool, one holder" method is beneficial for shops like Apollo that use many different tools, because it allows operators to avoid changing tools in and out of holders during machine setup. Each receptacle accommodates only specific retention studs, so a tool for one type of machine will not fit properly into a receptacle for another. This helps operators avoid accidentally mixing up tools from different types of machines.

Some manufacturers have logistical difficulties with unloading and storing all the tools from a machine with a large-capacity tool carousel for maintenance or other reasons. Tool Wall provides such shops with a large enough storage capacity to match the number of the carousel’s tool pocket to the Tool Wall receptacle number. This is said to make removal and replacement of tools more straightforward and to ease the sharing of large numbers of tools among different machines.

However, despite owning a great number of tools, small- and medium-sized operations like Apollo often don’t have such large-capacity tool magazines. Likewise, such shops commonly find that in-machine measuring systems, which can reduce the extensive tool-handling and setup time that comes with short-run jobs, can be prohibitively expensive. Apollo’s products, hydraulic manifolds for the agriculture, marine, mining, wood, and oil and gas industries, are commonly manufactured in batch sizes amounting to no more than 10 or 20 parts. In some cases, these low-quantity orders led the shop’s nine employees to spend as much time setting up its Haas and Daewoo machining centers as they did actually machining the manifolds, Mr. Brett says.

Prior to implementing the Tool Wall, operators had to install all needed tools into the machines based on a master list compiled by the lead machinist. Without an in-machine measuring system, they had to zero each tool on a reference block to determine proper offsets. Those numbers were then entered manually into the machine controls. "If you’re dealing with 18 tools, you have to do that 18 times," Mr. Brett explains. "Every hour that you’re doing setup, you’re not making chips." Addressing these issues required more than just compact tool storage. The shop wanted a system that would track its tools and automatically input offsets and other data into the machine control. This would eliminate the time-consuming procedure of performing tool-length measurement on the machines. With this goal in mind, Mr. Faust hired a full-time programmer to develop a software package that would complement the storage wall itself.

The resulting program tracks the locations of all tools, whether mounted in the Tool Wall receptacles or in a CNC machine. When moving a tool from Tool Wall to a machine or vise versa, the operator simply inputs the corresponding pocket number into the system’s touchscreen interface. An external tool presetter mounted below the touchscreen enables users to measure all tools outside the machine. The software stores all tool length and diameter data and calculates proper offsets according to the zero points of the various machines in the shop. That data is automatically uploaded to the machine control when the program runs, eliminating the need for repeated manual entry of offsets before every job. Preferred feeds and speeds can also be stored and retrieved when needed.

A beta version of the software has been running for some time at Apollo, and it has surpassed the shop’s initial goals. However, the product has evolved significantly since its inception. In addition to storing tool data and uploading offsets, the upcoming consumer version of the software tracks machine running time as well as consumable use and inventory, and it automatically generates reorder lists by part number and vendor. "We started with just an offset upload system, but now it’s turned into quite a powerful software suite." Mr. Brett says.

A new module slated for release with the consumer version, Synchronized Automation Management (SAM), is currently in the final testing stages, Mr. Brett says. SAM integrates tool data and other information needed for each job to automate the job preparation and tool setup process. The software notifies operators which tools are needed and where those tools are located, whether in a machine or in the Tool Wall.

"For example, if eight of the ten tools required for a job are already in the machine and two are in the wall, the software tells you to put those two into the machine and tells you which pockets are empty," Mr. Brett explains. He adds that SAM can automatically assign tool pockets close together based on their sequence in the program. This helps avoid pauses in machining while the magazine turns to engage the next required tool.

The system requires the Tool Wall receptacle number to be programmed in all master G code. Once all needed tools are installed in the machine, the software generates a working code file that changes the Tool Wall receptacle numbers to the corresponding pocket numbers in the machine’s tool magazine. The master code is never changed, but by keeping track of tool locations and rewriting the working G code file to match machine pockets, the software minimizes tool handling and setup time, Mr. Brett says. "Before we were using this, we’d have to remove all the tools from the machine and put them back," he explains. "Now, we maybe take one or two out and put one or two back in. On a 10-tool program, we could go from 50 minutes of setup to less than 5 minutes."

Apollo hopes the system will create a new standard for CNC machine setup. Mr. Brett says this is sorely lacking in today’s shops, each of which has its own method for setting up machines. "As a complete package for a machine shop, there is nothing like it on the market," he says. "We feel that once people experience it, they won’t want to go back. In that sense, we are essentially setting a standard."

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)