To See Machining Reality on a Tablet

Viewing the simulation of a live machining process in real time gives clear picture of what is happening at the moment inside the machine tool as it runs an NC program. SPRING Technologies’ NCSIMUL Player Synchro makes this happen on a wireless mobile tablet with an app called WYSIWYC.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

One of the distinguishing aspects of the CNC programming aids from SPRING Technologies (U.S. offices in Cambridge, Massachusetts) is advanced use of 3D simulation of machining processes, which the company has taken in several new directions. One of the most interesting of these developments is a mobile application called WYSIWYC (what you see is what you cut) that puts its NCSIMUL Player Synchro on a tablet PC designed to withstand a harsh environment.

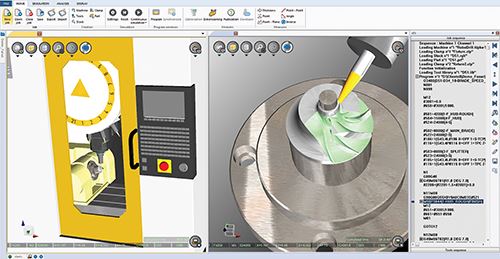

Synchro is based on the company’s simulation viewer, NCSIMUL Player, which enables users to analyze, manipulate and display NC programs and machining simulations generated by NCSIMUL Machine, the company’s advanced 3D machining simulation capability. These simulations include machine kinematics and parameters in the machining context.

Player Synchro provides a way to view the simulation of a live machining process in real time; in other words, the display of the simulated machining process is synchronized with what is happening at the moment inside the machine tool as it runs an NC program. For example, when the display shows a cutter milling the surface of an impeller blade in five axes, the actual cutting tool inside the machine is also contacting the workpiece in the same operation and orientation at the same instant. This approach enables the viewer to watch the machining process in progress without coolant spray or ricocheting metal chips to block the view. Machining operations and cutting conditions can be seen more clearly and accurately as a result.

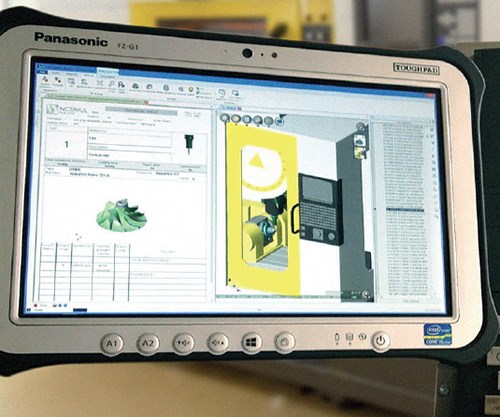

WYSIWYC takes this concept one step further by embedding this live, synchronized simulation capability on a tablet PC. The tablet of choice for this solution is the Panasonic Toughpad FZ-G1 because this device is designed for the harsh environments often encountered on the shop floor. This tablet-based solution is portable—it connects wirelessly to the shop network for viewing. The touchscreen user interface offers multitouch gesturing to control image size and other display characteristics. In addition to simulations, instruction sheets and work-sheets are accessible directly from the mobile application.

The tablet solution also enhances the capability of the Synchro application for multi-machine supervision. With this capability, the user can access multiple displays to monitor and attend to several machines from one viewing station, thereby reducing the concern that any event requiring immediate attention will be overlooked while tending to a contingency on another machine. To be accessible, machines must be logged onto the network and have simulations available in NCSIMUL Machine. The portability of the tablet enables the user to move about the shop floor at will, yet never be out of touch with immediate observation of the machines under that user’s watch. Because the 3D machining simulations are said to be highly realistic and accurate renderings of machine axes, spindles and cutting tools, the tablet is a virtual window into any and all of the assigned machines.

The latest enhancements to Synchro, which also extend to the mobile application, include anti-collision “radar” and adaptive timers. The radar feature provides a dynamic display of available travel in each axis when jogging the machine into position in the manual mode. This makes potential collisions easy to detect visually even when the line of sight is blocked with normal, eyes-on viewing. It also provides added security when running in the auto mode. The adaptive timers are displayable reports that show up-to-the-moment summaries of machine downtime, tool changes, end of program, part cycle times and other machine activity in a dashboard-like format. This creates an opportunity to identify operational factors that can be improved to increase productivity and utilization.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)