Surface Texturing with Laser Ablation

Much of a product’s appeal to the consumer has to do with its look and feel—literally, the texture of its visible surface.

Share

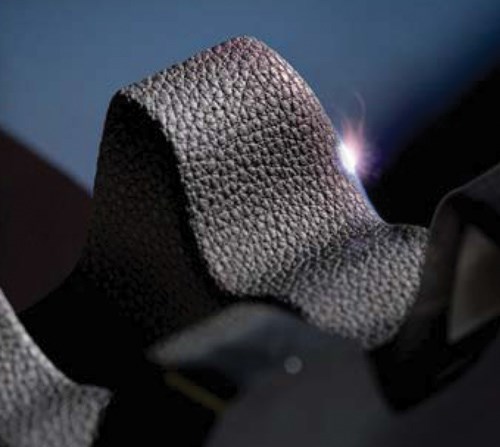

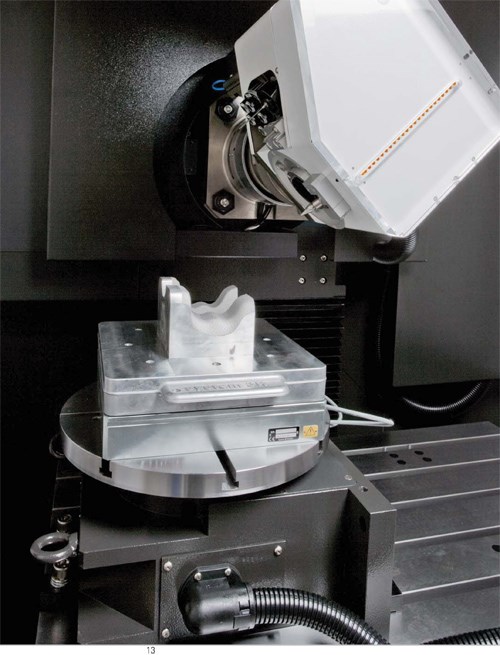

Much of a product’s appeal to the consumer has to do with its look and feel—literally, the texture of its visible surface. The pattern of tooled leather, the weave of a rich fabric or the grain of weathered wood pleases the eye and gratifies the touch. Reproducing such textures on metal workpieces is one of the primary applications for a line of laser-powered machine tools from GF AgieCharmilles (Lincolnshire, Illinois). The three- and five-axis models in this line use a high-powered laser beam that impinges on the workpiece surface under high speed computer control to remove material by ablation, thus creating virtually any surface texture that can be digitized. Ablation can be described as a method to melt and vaporize a workpiece material with high heat.

In addition to texturing, this process can be used to engrave, mark, label or render a microstructure on a surface in 2 or 3D. According to the company, this process can be applied to aluminum, copper, steel, graphite, carbide, brass, ceramics and other materials. Laser ablation is said to be more flexible, predictable and environmentally benign than acid etching or other conventional surface treatment.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More