Six Ways to Make 5-Axis Machining More Productive

Sponsored ContentFive-axis machining is growing in popularity because of the dramatic efficiencies it can bring in an increasingly broad range of applications — from aerospace to medical to production parts as well as dies and molds. Good CAM software is critical to unlocking that potential.

Share

All manufacturers are under pressure to make their operations more efficient. That means getting more from your investments in both production equipment and people. Automation is increasingly part of that equation but for many shops the topmost priority is getting more from the equipment they already have.

One area where shops are seeing significant returns is with five-axis machining centers. It’s not just about machining complicated parts more quickly and to higher quality standards. It’s also about doing more to finish a job in a single setup. Being able to get at multiple sides of a part as well as 3D intricate workpiece features can pay huge dividends in reduced total cycle times while delivering better dimensional accuracy, surface finish and tool life.

For a lot of shops, the limitation in 5-axis machining is not so much in their equipment, but in their ability to efficiently generate part programs that make best use of today’s machining centers and cutting tools. But with advances in CAM software those imitations are falling quickly if shops are willing to avail themselves of the newest programming technology.

CAD/CAM developer Siemens Digital Industries Software has made the continuing development of five-axis machining capabilities with its NX CAM software a priority and has a lot to say about what strategies will best enhance both the programming and machining processes. Whether you do die/mold work, aerospace, medical, energy or production machining, here’s more on what you should look for in the newest innovations in this very productive technology.

1. Guiding Curves tool paths follow the flow of surface topography for smoother surfaces

Guiding Curves applies tool paths directly on the machining area with full control of the tool path flow

Guiding Curves is a finishing operation that lets you create 5-axis tool paths directly on the machining area with full control of the tool path flow. No more creating projection surfaces in CAD and then trying to figure out which direction to project the tool path on the machining area. You have access to precise tool axis control whether you want to stay normal to the surface, interpolate between several tool axes, lock an axis and so on. It also automatically provides tool path smoothing as the path moves from one position to the next.

This video shows the Guiding Curve 5-axis programming process for a ballnose endmill including curve selection, stepover (scallop), tool vector, and process simulation.

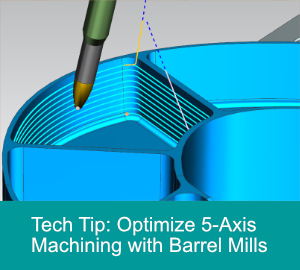

2. Barrel Cutters more efficiently shape curved and sloped surfaces

Barrel cutters (left) more efficiently machine sloped and slightly curved walls with much larger stepdowns in comparison to ball nose end mills (right).

Barrel cutting tools are used for a variety of machining operations, but what they are really good at are roughing and finishing flat and slightly curved walls in 5-axis machining. Because of the shape of the barrel tool you can get the same and usually better surface finish with a much bigger step down. By using these tools for advanced cutting strategies you can reduce machining time of some features by as much as 70% compared to machining with ball nose end mills.

Using a barrel cutter in this finishing test cut was almost three times faster compared to a ball nose end mill. Video courtesy of Fraisa.

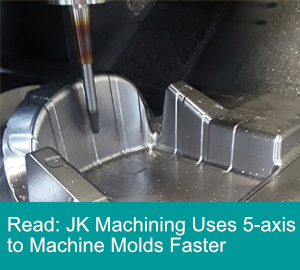

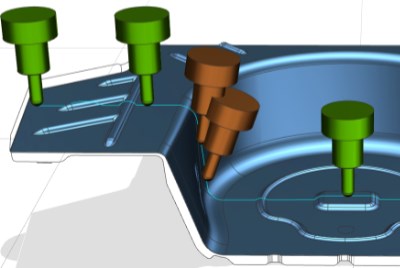

3. Automatic 3-to-5 Axis Tilt avoids toolholder collisions

Automatic 3-to 5-Axis Tilt adjusts the tool vector for situations where the toolholder or spindle would collide with adjacent surfaces.

One of the great advantages of 5-axis machining is the ability to tilt the tool away from pocket or cavity walls to avoid toolholder or spindle collisions. This allows the use of much shorter tools which enables more aggressive machining yet with reduced vibration and better surface finish. This is an ideal strategy for parts with deep cavities and fine features next to tall walls. With a 3-to-5 axis tilt feature in CAM, you can program the tool path in a more familiar 3-axis mode and the software will then automatically adjust the tool vector for situations where the toolholder would collide with adjacent surfaces.

JK Machining, a Michigan-based manufacturer of top-quality class 101 molds, is leveraging this 5-axis cutting method. Using shorter tools and higher cutting speeds, JK slashed their machining time by as much as four times. Additionally, the reduced chatter helps them machine high quality surface finish. Go here for more on JK Machining.

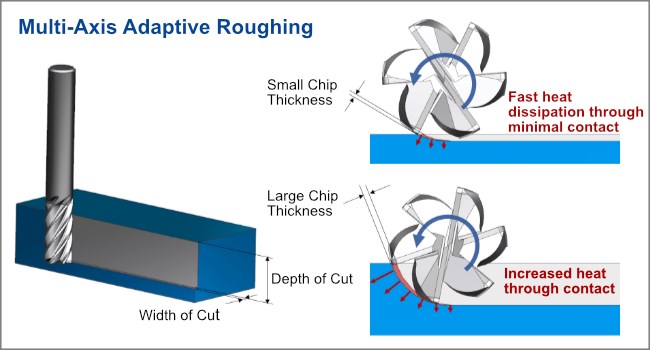

4. Multi-Axis Adaptive Roughing reduces cycle times

Whether dealing with a mold cavity or a prismatic shape, the fastest way to remove material is with a high-speed, adaptive roughing cycle. First off, with a 5-axis process, you can get closer to the semi finish shape of the part which can significantly reduce finishing cycle times. Add adaptive milling and the total cycle time reductions can be dramatic.

With a smaller stepover but much larger depth of cut, Multi-Axis Adaptive Roughing enables faster feeds and higher metal removal rates.

With adaptive milling you reduce the radial depth of cut (stepover) to less than 25% of the tool diameter but significantly increase the axial depth of cut. Because chip thickness is now much smaller than the centerline feed per tooth, you can substantially increase the feed rate. This results in light, fast cutting action, enabling more aggressive cutting and faster metal removal rates, which can reduce machining time by up to 60%. It also generates less heat and vibration in the cutting zone, which in turn supports secure, predictable cutter wear.

This video shows a block of Steel 850-1100 N/mm2 being machined with the 5-axis Adaptive Milling tool path technique. The roughing routine uses helical interpolation to enter the material, then takes light, fast cuts, quickly removing material. Video courtesy of Fraisa.

The key to making this process work is the ability to maintain a constant cutting force throughout the roughing routine. For example, running a tool into a corner suddenly increases material engagement and causes cutting forces on the tool to spike. This and other rapid changes in cutting force create shocks that can lead to chipping, poor surface finish and substantially reduced tool life. With Adaptive Milling the toolpath is automatically altered to maintain a constant chip load which results in faster, smoother cutting. The technique is particularly beneficial in roughing cores and cavities in tool steels as well as pocketing in HRSA materials such as Inconel and titanium. It combines high metal removal rates in these difficult materials and longer, more predictable tool life.

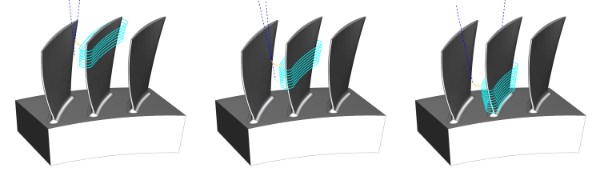

5. Turbomachinery Milling machines impellers and blisks in half the time

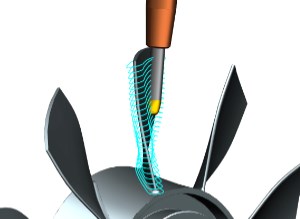

Turbomachinery Milling simplifies programming of multi-bladed rotational parts such as impellers, blisks, blades and shrouded turbines. View full size.

Siemens NX software’s Turbomachinery Milling simplifies the NC programming process for machining complex 5-axis multi-bladed rotational parts such as impellers, blisks, blades and shrouded turbines. With a suite of process-specific functions specifically designed for these kinds of parts, NX CAM’s Turbomachinery Milling enables optimized part programs to be created more quickly with substantially shorter cycle times, better surface finish and longer tool life.

New advancements to Turbomachinery Milling include:

- Multiple Stripe Cut Level Support which allows for precise dividing and blending of surface segments on turbomachinery blades. The stripe cut levels feature allows the tool path of the blade to be broken into top, intermediate, and bottom sections that can be independently controlled and then seamlessly blended between the separate cutting operations.

Multiple Stripe Cut Level Support allows the segmenting of blades to optimize machining for those surface zones.

-

Tangent Barrel Tool Support brings the same benefits that barrel cutters provide to mold and prismatic part machining to blades and other spline curved walls. These surfaces can be machined more than 50% faster compared to finishing with ball nose end mills, and with better surface finish and tool life.

Tangent barrel cutting with Siemens NX Turbomachinery Milling.

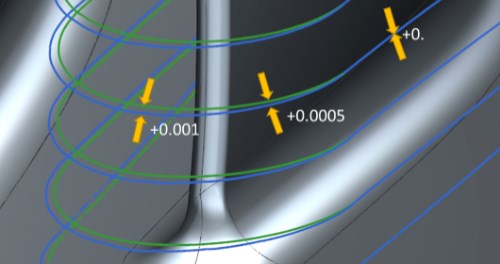

- Custom Stock Offsets allow you to adjust the amount of material left behind on the blade for precise control of stock removal in semi- or final-finishing operations. This advanced function, used by aerospace engine manufacturers that have stringent tolerance requirements, enables highly-accurate machining that can compensate for the thin blades’ flexible deformation during the cutting operations.

Custom Stock Offsets allows precise control over the amount of material left behind.

6. Turn Milling provides better utilization of multitasking machines

Turn-milling is an excellent technique for machining circular or conical shaped surfaces with feature obstructions.

Not all 5-axis processes happen on 5-axis milling centers. Particularly with larger round casings, shafts and other difficult-to-machine components, executing 5-axis machining on a turn-mill center often will be the most efficient way to machine complicated workpieces in a single setup.

Turn-milling is an excellent technique for machining a lot of material quickly out of circular or conical shaped surfaces with feature obstructions – such as bosses and split seam flanges. These operations can be accomplished with indexable, solid, ceramic, carbide, round, high feed, and wiper tools. This makes turn milling an ideal solution for roughing and finishing with excellent surface tolerance and finish when a wiper inserted tool is used.

In this video you can see an example of rough turn-milling on a multi-tasking machine. This is a ceramic indexable endmill cutting Inconel 718. The combination of cutter and technique make for extremely fast roughing of difficult-to-machine nickel alloys. Video and image courtesy of Sandvik Coromant.

With turn-milling, cutter positioning in relation to the part surface is critical. It is important in most applications to cut the material on the leading edge of the cutter. This will prevent back cutting of the part surface, improving cutting conditions that can prolong tool life.

What’s next for multi-axis machining?

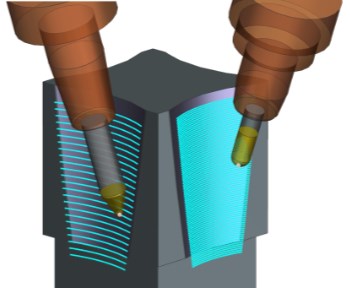

One emerging alternative is using robots for machining certain kinds of parts. Why? For one, robots enable cost effective machining of much larger workpieces where you can bring the machining envelope to the part rather than the other way around—for example, to drill holes in an aircraft wing or fuselage. Robots are also able to execute post-machining operations such as polishing and deburring that would otherwise require manual work, and improve the accuracy and quality of those operations as well. This enables both machining and finishing in a single automated process. In an automated work cell, robots can be used both for machine tending and machining, or maybe replace a very expensive machine tool altogether.

But are robots accurate and rigid enough for real machining operations? The latest generation of robots has made great strides in this regard with the ability to perform accurate high-force machining, and development is ongoing. In one project Siemens is working with the Technical University of Munich to machine to very high levels of precision (see video). Employing a digital technology called simulation-based force compensation, they have been able to achieve tool path accuracy of 100 microns (μm). With results like this robotic machining is poised to serve a growing range of applications.

Using robots for precision machining is the focus of this joint project by Siemens and the Technical University of Munich. The simulation-based force compensation method enables robots to achieve tool path accuracy of 100 μm.

The Best Process for the Job

Whether you are a job shop or a product line manufacturer, mastery of 5-axis machining can provide a strategic advantage to your business. You can produce complex parts with fewer operations and setups. In many cases, you can reduce machining time and improve tool life, while improving part quality. And you can cut production costs and deliver parts faster.

There was a time when making the most of an investment in multi-axis machining could be severely limited by the time and difficulty required to create efficient programs that truly capitalize on the capabilities of this equipment. That time has passed. With today’s best CAM technology you can realize the full promise of 5-axis machining with an ROI that surpasses many other machining methods.

Go here for more information on Siemens NX CAM software.