Radar-Based Collision Protection

Researchers are working toward radar-based collision protection for machine tools. Here are some thoughts about what a development such as that might mean.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

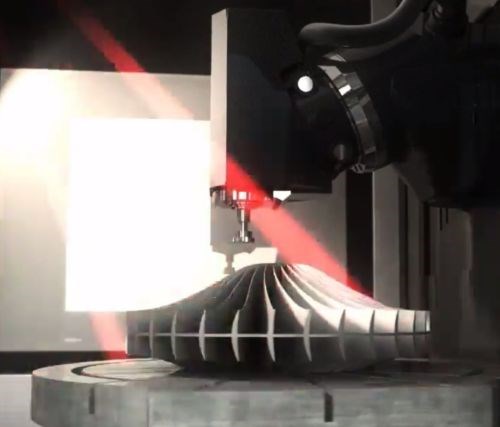

This animated video of a future machine shop envisions a non-contact scanning system ensuring collision avoidance within the machine. The idea is not that futuristic. Researchers today are working toward radar-based collision protection for machine tools. Here are some thoughts about what a development such as that might mean.

Related Content

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.jpg;maxWidth=300;quality=90)