Published

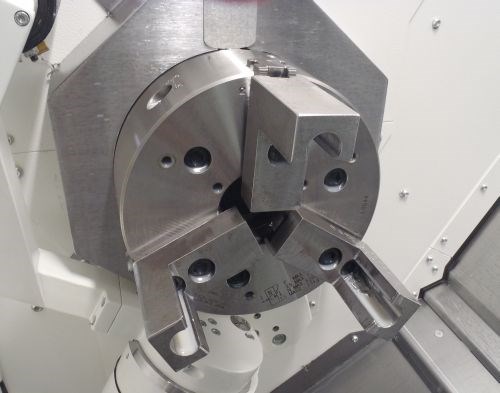

Quick-Change Chucks Offer More than Fast Jaw Changes

For this shop, eliminating the need for reboring is the most important benefit of QJR quick-change chucks from Kitagawa-Northtech.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Bringing machining in-house for the first time in 2008 was a major milestone for Midwest Pressure Systems (MPS), and it was only a few years later that the shop doubled down on that commitment by replacing its multiple mills and lathes with two Integrex turn-mills from Mazak. As detailed in this article, QJR-series quick-change chucks from Kitagawa amplified the benefits of that move—but not in the way you might initially expect.

MPS changes jaws an average of once per week, barring any especially urgent work. At that rate, you might assume that the ability to swap jaws quickly might not be as important for MPS as it is to manufacturers that perform more change-overs. And you’d be right. According to the shop, the greatest benefit of these chucks is not from quick-change capability, but the jaws’ ability mount to the chuck body with sufficient precision to eliminate the need for reboring.

Suffice to say that paying close attention to options and peripherals can make a big difference in any sizeable equipment investment. You might even find that a product’s advantages extend beyond its most touted or most obvious features and capabilities.