Production Machining Center Integrates Rotary Transfer Concepts

A new machine platform combines CNC rotary transfer philosophy with machining center principles to offer an alternative to stand-alone production lines and flexible machining systems.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreCNC technology has increased the flexibility of rotary transfer machines to the point that they can be used for more than just dedicated, high-volume production work. Some of these machines are now viable alternatives for medium-volume jobs and even relatively small batches, in some instances.

Hydromat (Saint Louis, Missouri) has developed a new machine platform that it says melds the company’s CNC rotary transfer philosophy with machining center principles to offer an alternative to stand-alone production lines and flexible machining systems. Its Icon “productivity machine” also can produce parts that are larger than most conventional rotary transfer machines can accommodate.

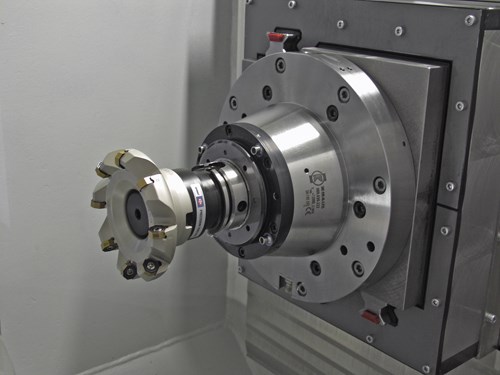

The six-station Icon can machine parts ranging in size from 2- to 8-inch cubes. At the heart of the machine is a rotary table that transfers six 300-mm workholding pallets to the machine’s six stations (table rotation time is 4.5 seconds). Four of these stations (located at positions 2, 3, 5 and 6) can be fitted with both vertical and horizontal milling spindles, enabling eight tools to cut at the same time. Each spindle offers 29 kW of power and maximum speed of 12,000 rpm. Pallet B-axis rotation provides the spindles with access to fives sides of a part and enables simultaneous, four-axis machining operations. Each spindle has a dedicated 10-tool, disc-style automatic tool changer that accommodates HSK 63 toolholders (optional 80-bar-pressure coolant through the spindle is available).

The loading station at position 1 allows manual or robotic loading/unloading, while the opposing station at position 4 can be used for gaging, re-clamping or part loading. Inner and outer doors are located at these two non-machining stations. The inner doors keep chips and coolant within the machining zone so that operators can safely handle workpieces while during machining operations. Standard Fanuc 300i controls are located on either side of the machine at positions 1 and 4 for operator convenience.

.png;maxWidth=150)