Positive Correlation between Robots and Employment

Do robots replace employees? Far from it. Data suggest employment and automation grow together, while individual cases show automation raising employee value and helping the employer attract talent.

Share

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

What is the relationship between robotic automation and employment? The relationship would seem to be an inverse one. That is, as the use of robots increases, employment should go down—or so we might expect.

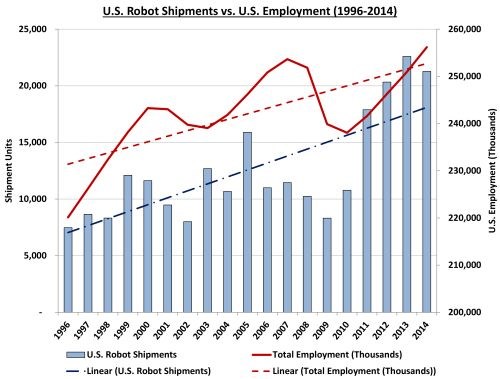

A new white paper from the Association for Advancing Automation (A3) demonstrates that this expectation is false. Robots do not appear to replace employees, because the correlation between them is positive. When robot shipments have gone up, employment has gone up at the same time.

U.S. employment data compared to U.S. robot shipments show this. During periods when robot sales were increasing, employment has been generally increasing as well. The correlation was particularly apparent from 2010 to 2013, when both U.S. employment and U.S. robots sales grew steadily. (Employment then dropped a notch in 2014, while robot sales continued to grow.)

The paper also gives examples of companies that have increased both employment and the use of robots. Marlin Steel is one these. The company’s CEO, Drew Greenblatt, is quoted. “Not only has changing over to an automated production process saved our company from the threat of bankruptcy, saving the jobs of everyone here, it has allowed us to expand our work force,” he says. “Since going automated, Marlin Steel has nearly doubled the size of the work force, adding engineers and automated production specialists to our existing team.”

Those job types he mentions suggest another aspect of automation’s impact on employment that the A3 paper also addresses. Namely: The jobs added are often higher in responsibility and compensation than what was typical of the company’s workforce before it increased automation.

Robots, in fact, are helping with the need to attract talent to manufacturing. Vickers Engineering CEO Matt Tyler sees this. After his company’s shift to automation, he says, “We’re now able to attract people who aren’t just looking to draw a paycheck, they’re looking for a career.” Vickers senior automation engineer Jordan Klint adds, “In order to bring young people into the business, you have to have technology. The guys who report to me really enjoy the robotics side. They think robots are cool.”

Obtain the white paper at A3automate.org, and read further thoughts about the relationship between robots and employment here and here.

Related Content

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.png;maxWidth=150)