Okuma’s Aim Is True

This video series about how the company’s CNC machines are used to manufacture gun parts sets its sights on opportunities to enter a booming market.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Okuma has released a series of videos demonstrating how its CNC machines are used in manufacturing gun parts. The six videos currently posted on YouTube demonstrate the machines and processes necessary to manufacture the following parts:

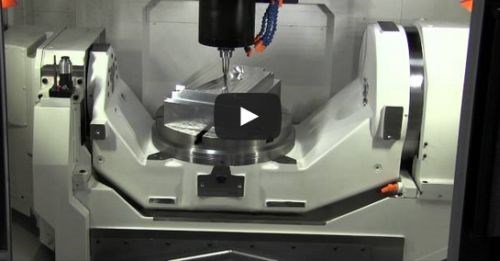

- Rifle Stock Mold—In the video embedded above, a five-axis vertical machining center cuts a custom-designed rifle stock mold

- AR15 Upper—A horizontal machining center machines an AR15 upper

- Gun Barrel Extension—Cut on a horizontal lathe, the machining of this gun barrel extension uses a variety of cutting tools and operations

- Commemorative Plaque—this video shows the CNC milling of a gun-shaped plaque for a firearms event

- 1911 Trigger Housing—Machining of a 1911 trigger housing using a vertical machining center equipped with a rotary table

- Gun Cylinder—A .50 caliber revolver cylinder is cut on a three-turret horizontal lathe

There are clearly opportunities for growth in this market. According to the Annual Firearms Manufacturing and Export Report compiled by the Bureau of Alcohol, Tobacco, Firearms and Explosives (U.S. Dept. of Justice), some 8,578,610 guns—including pistols, revolvers, rifles, shotguns and miscellaneous firearms—were manufactured in 2012, the last year for which complete figures are available. This is up from 6,541,886 in the same categories manufactured in 2011. Have you had success working in this particular market? Share your story here.

.png;maxWidth=300;quality=90)