No Gloom And Doom At IMTS

September’s big show in Chicago indicated that investment in new manufacturing technology is likely to remain relatively strong despite uncertainty in other sectors of the economy.

Share

Autodesk, Inc.

Featured Content

View More

Despite what you hear in the news, American manufacturing has a lot of vitality. Manufacturing remains strong in the United States and North America.” Remarks such as this were expressed over and over by top officials at companies exhibiting at the International Manufacturing Technology Show (IMTS), which took place in September at Chicago’s McCormick Place. Surely, these remarks reflect the strong orders for machine tools, tooling products, programming software and other equipment that most suppliers to the industry are experiencing right now.

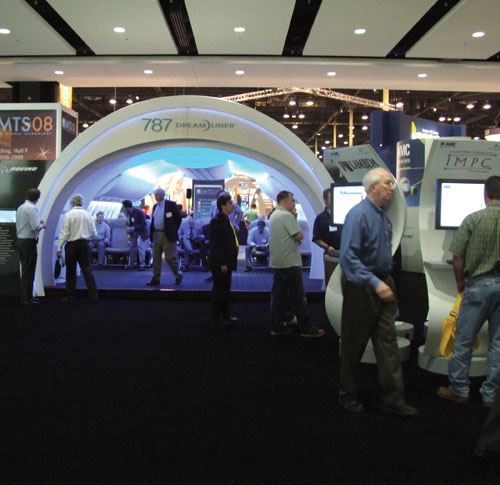

The mood among attendees was upbeat as well, and their interest in new technology was high. Total registration, as reported by the IMTS Exhibitions Department, was 92,450—the highest attendance since the year 2000, even though this show was shortened to 6 days. Show-goers had a lot to see in those 6 days. More than 1,800 companies exhibited at the show, filling more than 1.23 million square feet of exhibit space, including the new West Building that housed the Tooling and Workholding Systems Pavilion and MMS’s own Advanced Manufacturing Center (a big hit!). It was a big show and a busy one.

With current headlines filled with talk about turmoil on Wall Street, consumer anxiety on Main Street and clashing political views from Pennsylvania Avenue, the positive outlook that permeated IMTS ought to be kept in mind. Those of us in manufacturing may have more reason to be optimistic than we might otherwise think.

In terms of new technology at the show, the best piece of good news seemed to be the strong interest in MTConnect, a new communications protocol standard for passing data between devices, equipment and higher applications. Quite a few exhibitors promoted their implementation or endorsement of the standard. In one case, an exhibitor took a look at MTConnect when the show started and liked the concept. Reportedly, engineers at the company had a fully compliant adapter up and running in 6 hours—a testament to both their technical prowess and to the high quality of the MTConnect development effort.

For a closer look at this standard, visit www.mtconnect.org. Otherwise, many of the technology trends evident at IMTS 2008 were the same as at recent past shows. A few differences or nuances are worth noting.

• Automation is getting simpler. Mechanical devices for transferring parts, pallets and tools are more compact, easier to program, easier to integrate with other control systems and more likely to be available as a package from a single OEM. More users are beginning to see automation as a form of lean manufacturing that reduces setup, promotes single part flow and frees up both precious floor space and skilled workers.

• Big machines were plentiful. Large horizontal boring mills and flatbed lathes with large spindle bores were conspicuous. Activity in the energy, oilfield and power generation markets is a key factor driving interest in these machines. Wind turbine components were prominently displayed. Machines that handle large aerospace components were also featured in many booths.

• Green is a good thing. Many exhibitors were touting the energy efficiency of their products or the potential for reduced environmental impact. Cooler running electric motors, for example, save in three ways: They draw less power, they minimize adverse thermal effects and they reduce demand on chillers or other heat countermeasures. Minimum quantity lubrication (MQL) was another technique featured for its environmentally friendly aspects.

• Multiple process machines continue to evolve. The proliferation of multitasking machines has been a striking feature of every IMTS for some time now. Noticeable at this year’s show was a shift of attention from turning center platforms with milling capabilities to machining center platforms configured for turning and other

operations.

A collection of items that caught our eyes at the show can be viewed at an online slideshow we created (find a link to the slideshow under "Editor Picks" at the top-right portion of this page). This selection is not meant to represent anything but the curiosity and interest of the editors. It is true that attendees go to IMTS with better plans and more detailed agendas than in the past, but the benefits of roaming the aisles for unexpected discoveries is still respected. View the online slideshow with the same open mind.

The next IMTS is scheduled for September 13 through 18, 2010.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)