New Tool, New Strategy Allow Five Times Faster Roughing

This shop realized a tool designed for fast feeds and shallow cutting depths could reduce the roughing cycle time of a large shipyard component from 20 to 4 minutes.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

When a big new job arrives, it’s best to phase it in smoothly so as not to risk disrupting operations on your bread and butter work. Tom Young recently faced this situation. Mr. Young is a programmer at D&G Machining, a contract shop in Westbrook, Maine that specializes in large parts, many of which go into U.S. Navy ships.

That new job D&G took on looked as if it might become a production bottleneck. Completing a prototype took twice as long as planned, and a lot of tools broke unexpectedly. Full-lot production simply couldn’t begin until the company found a more effective way to machine the part.

The part is a chromium-steel guide rail used in a shipboard cargo handling system. It measures 36 inches long, has a 6- by 3.5-inch cross section and requires a square channel to be milled down its entire length. The initial order was for 350 parts.

The planned sequence was to rough the channel to within 0.050 inch of final size, send it out for hardening and then perform a finish-milling operation. Roughing the square channel proved to be the potential prime bottleneck. D&G originally estimated that the roughing operation would take 10 minutes, expecting inserts to last through several parts. However, the prototype took 20 minutes and broke the two-sided inserts badly enough to ruin the second edge.

The original cutter chosen for the job was a square-corner mill, which is D&G’s standard tool for channeling work. The 1.25-inch, three-flute cutter used two-sided rhombic inserts and a lead angle of zero. D&G ran the tool with a water-soluble cutting fluid. The lead angle was zero, so cutting forces were mainly in the lateral direction. The fastest the tool could cut without deflecting was 400 sfm and 9.6 ipm at a 0.350-inch depth of cut (five passes were needed). This took about 20 minutes per piece.

Fortunately, Mr. Young had just returned from an Ingersoll “Productivity Redefined” tooling seminar, highlighting the importance of focusing on maximizing removal rates, minimizing machining costs and freeing-up machine time rather than quibbling over initial tooling costs. One of the tools demonstrated at the seminar was Ingersoll’s new Power Feed+ cutter, which is specifically designed to speed rough-milling operations.

After the seminar, Mr. Young contacted Ingersoll’s Bob Bornheimer to help determine if the Power Feed+ shown at the seminar might be the solution to his roughing problem. Mr. Bornheimer agreed with Mr. Young’s tooling choice while recommending a different strategy: taking a series of shallow passes at a faster feed rate instead of deep passes at a slow feed rate. He believed this would improve the material removal rate and reduce the radial cutting forces.

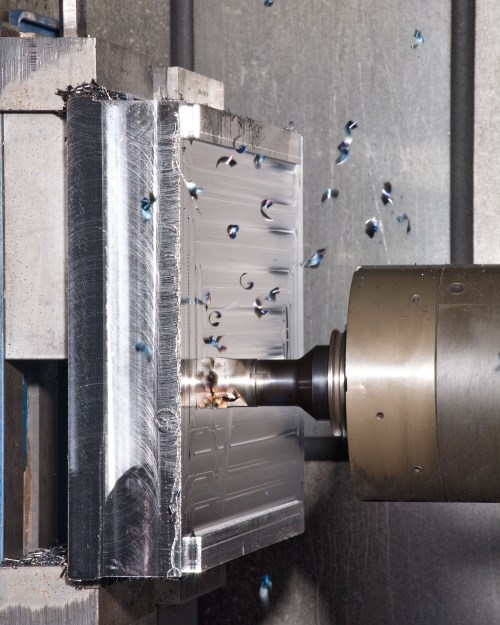

The trial tool arrived the morning after consulting with Mr. Bornheimer, and Mr. Bornheimer visited the shop that afternoon to assist in integrating the tool. The two gentlemen, along with D&G programming supervisor Randy Wakefield, experimented with several machine settings. They finally settled on 1300 sfm, 350 ipm and a 0.050-inch depth of cut. Milling dry at those cutting parameters reduced the roughing cycle time from 20 to 4 minutes, and the inserts lasted six times longer.

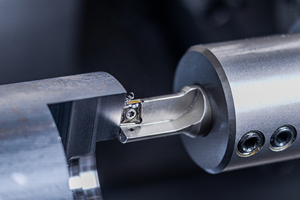

Although both the original tool and the new one have three flutes, there are significant design differences between the two. The Power Feed+ cutter is engineered specifically for fast-feed-rate, shallow-cut milling generating minimal radial cutting forces. The insert is thicker, thus is stronger. Its trigon shape does a better job of maximizing chip thinning than a rhombic shape. (Chip thinning yields a chip that’s thick at the front but thins toward the end.) This chip-thinning effect is said to reduce the power to remove a given volume of metal by as much as 30 percent. The trigon inserts also develop a consistent, heavy chip that carries away more of the heat at high feed rates. A 10-degree lead angle enables gentle entry into the workpiece, reducing lateral forces on the tool and machine spindle. In addition, the insert’s geometry redirects more of the cutting forces toward the Z axis of the spindle for greater stability.

The new tool and roughing strategy allowed D&G to turn a potential money-losing job into a profitable one while freeing up a key machine for additional work. Based on the success with the guide rail job, D&G has standardized on the “feed fast/cut shallow” approach with Ingersoll’s Power Feed+ for most rough milling operations in steel. In fact, when the cutter was used on the first job after the guide rail work, it performed a rough facing operation that previously took 1.5 hours in only 40 minutes.

Related Content

Ceratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreOSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreKennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)