Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

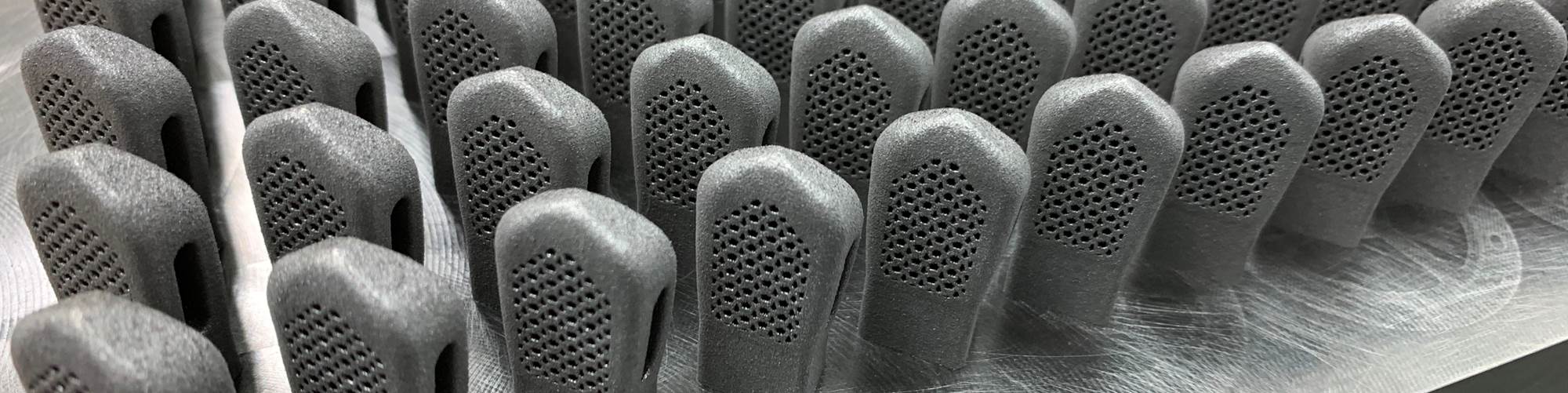

Additive manufacturing (AM) is arguably the broadest category of manufacturing out there. AM includes seven distinct families of 3D printing technologies, each containing many different varieties of the given process. It utilizes materials ranging from metal powder to liquid resins to composites, and delivers objects ranging from look-and-feel prototypes to all types of tooling to full-volume production runs. And, it is finding footholds in wide-ranging sectors, including aerospace, automotive, medical, defense, fabrication, architecture, consumer goods and more.

Whether in metals or polymers, for medical implants or aerospace parts, there can be hurdles to implementing additive manufacturing, as well as many advantages.

Top and bottom left images: Staff | Top right: Model No. | Bottom right: GE Additive

With so much to take in, it can be difficult for manufacturers to see the way forward with additive, or even how to think about bringing AM into their businesses. Over at Additive Manufacturing, sister publication to Modern Machine Shop, we’ve created an entry-level resource that breaks down the challenges and issues surrounding AM, but also the opportunities this technology stands to bring to its users.

Head to our New to AM? microsite to learn:

- What distinguishes the seven AM process families, and which techniques are most commonly used for production

- The various classes of materials it is possible to 3D print with

- Real-world use cases and applications for AM

- What to consider in developing an additive manufacturing workflow

- What equipment AM requires, beyond the printer

- How to think about the business side of 3D printing

- Trends that will drive AM farther, including artificial intelligence, distributed manufacturing and sustainability

Related Content

-

Go Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

-

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

-

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)