Nano Technology Improves Insert Coating Adhesion

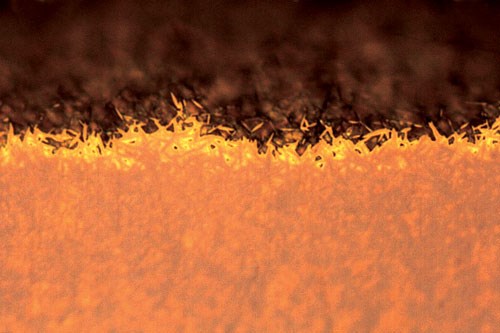

The needle-like surface structure of this TiCN insert coating interlocks with a succeeding layer of aluminum oxide to enable the insert to resist both heat and abrasion.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Titanium carbonitride (TiCN) is a coating that’s commonly used on cutting tools and indexable inserts. In fact, more than 90 percent of all indexable inserts coated via chemical vapor deposition (CVD) have at least one layer of TiCN, according to Reinhard Pitonak, engineer of research and development for Boehlerit (one of the six companies that constitute the LMT Group). Mr. Pitonak says the prime reason for the TiCN coating is to prevent insert wear.

TiCN coatings that contain very small carbon and nitrogen particles—those ranging in size from 50 to 300 nanometers—tend to possess good wear-resistance characteristics, Mr. Pitonak explains. To that end, Boehlerit developed a TiCN coating using particles measuring just 25 nanometers. What the company found was that the fine particle size combined with a very-high-temperature CVD coating process resulted in an unconventional, yet beneficial TiCN surface structure.

The nanocrystalline coating it created has a needle-like surface structure. This surface allows the TiCN coating, which the company calls Nanolock, to “interlock” with a succeeding layer of an aluminum oxide coating. This very strong adhesion between the two coatings makes the aluminum oxide, which offers protection against excessive heat during machining, less likely to delaminate during a cut. The combined abrasion-resistance properties of TiCN with the heat-resistance properties of aluminum oxide enables users to achieve higher cutting speeds and a longer insert life, Mr. Pitonak says.

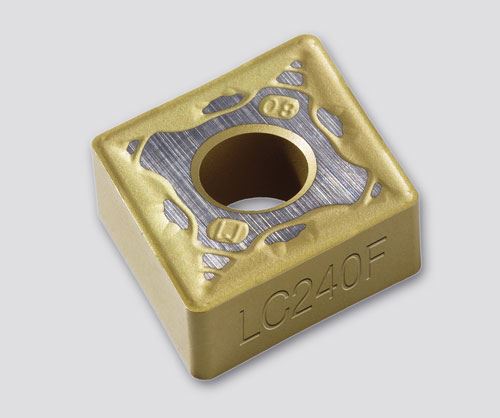

The Nanolock technology is currently available for Boehlerit’s LC 228E universal bar-peeling inserts, LC 239Q crankshaft-machining inserts and Steeltec rotary inserts. Cutting tests comparing the Steeltec grade LC 215K Nanolock inserts with conventional inserts resulted in Steeltec achieving cutting speeds higher than 300 m/min during a continuous cut in 4140 steel while providing 50 percent longer life.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

.png;maxWidth=300;quality=90)