Metalworking Fluid Increases Process Consistency

Integrating Chemetall’s Tech Cool 35052 metalworking fluid into its production process along with other production improvements helped Case New Holland improve machine uptime, tool life and part finish.

Share

When Case New Holland (CNH) began looking for ways to distinguish itself from the competition, the company took a closer look at its manufacturing practices. In particular, the chemistry of its metalworking fluid showed potential for improvement after residue and corrosion issues led to additional maintenance and tool wear. Along with other process improvements, switching to a semi-synthetic fluid enabled the company to improve machine uptime, tool life and part finish while reducing machine operation costs by 60 percent.

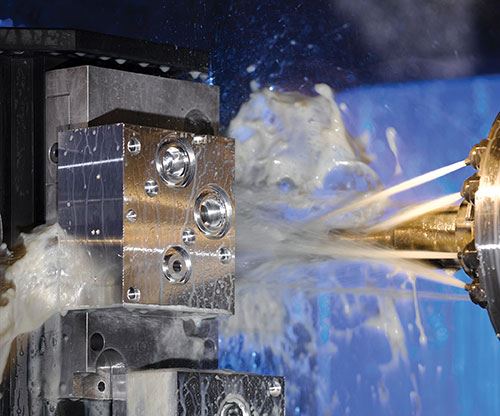

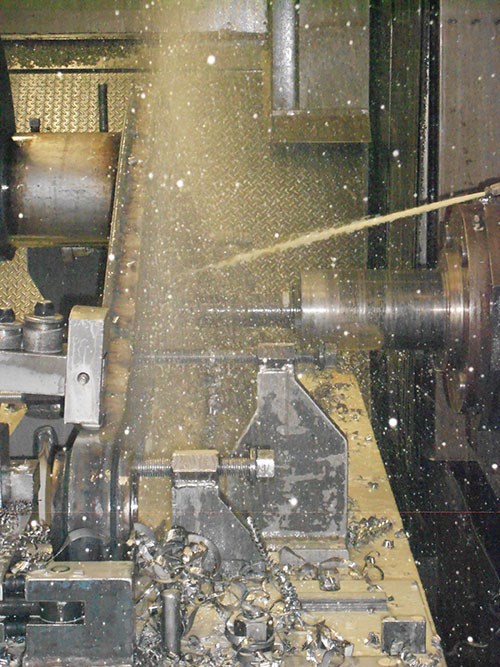

CNH is an American-based company operating on five continents in both the agricultural and construction equipment industries. Its 700,000-square-foot Fargo, North Dakota, facility employs approximately 700 people involved in the design, manufacture, painting and assembly of high-horsepower, four-wheel-drive agricultural tractors and wheel loaders. The company uses large horizontal and vertical machining centers to manufacture welded steel assemblies and other mild carbon steel components. These steel assemblies—some weighing between 3,500 and 5,000 pounds—require machining processes such as helical milling, boring, drilling, reaming and tapping. Standard tooling and specially designed indexable carbide inserts, super cobalt, tool steel, coated tools and carbide drills are used throughout the production floor.

Setting up these machines for repeatable, consistent performance is one of CNH Fargo’s biggest challenges, says Shaun Bratsch, manufacturing engineer. Predictable tool life and scheduled tool changes are critical for managing and meeting quality quotas at the plant’s maximum production rates. However, prior to 2012, it was common for spade drills to break and unexpected tool changes to interrupt production. Another disruption was caused by the high-lubricity synthetic coolant the company used, which left sticky residues that fouled the automated tool changers and caused corrosion. Additional maintenance, combined with the cost of tool wear and breakage, cost CNH an average of $20 per hour, per machine.

To minimize these interruptions and chart a smoother manufacturing process, CNH management met with its tool suppliers and implemented production improvements such as modifying chip breakers, introducing coated tools, improving tool design and providing additional training. Yet, even with the tool design changes, vibration analysis, clamping changes and machine maintenance improvements, the company realized there was still more room for improvement, specifically in optimizing metalworking fluid chemistry, fluid testing and on-site troubleshooting.

A team led by Mr. Bratsch and Manufacturing Engineering Manager Bill Moser worked closely with chemical supplier Chemetall (New Providence, New Jersey) to evaluate a new coolant program. After six months of evaluation, during which various machining cells were used to cover the plant’s most challenging operations, the group selected Chemetall’s Tech Cool 35052. According to the company, the high-lubricity, semi-synthetic coolant demonstrated no corrosion or sticky buildup. It also met both ASTM International and environmental health and safety (EHS) test methods for lubricity, foam, biological challenges, rust, health and safety.

As part of Chemetall’s “green line” of formaldehyde-free metalworking fluids, Tech Cool 35052 can be used to machine Inconel, stainless steel, forged steel, aluminum and other ferrous and nonferrous alloys. The micro-emulsion coolant is designed to maintain a highly stable emulsion under difficult conditions, reject tramp oil and provide extended sump life.

Using the new coolant and implementing programming changes, operators quickly noted increases in tool life. For example, spade bit uptime increased from 20 to 60 minutes. The extended tool life, along with the ability to increase cutting speeds and machine uptime, reduced the average cost per hour from $20 to $8—a 60 percent cost reduction that saved the company $188,000 annually.

Another benefit of the new metalworking fluid was an improved work environment. Eliminating the use of registered biocides enabled CNH Fargo to generate less waste and reduced corrosion, skin irritation and spindle maintenance. According to the company, odors were also reduced, even under longer periods of machine operation without dumping or cleaning the sumps.

The Tech Cool fluid is helping CNH Fargo reach its goal of driving the facility’s product quality toward a zero-defect environment. In fact, the company says it reduced its scrap rate associated with machining defects by 5 percent, while improving surface finish and quality. Fewer tool changes, maintenance requirements and sump change outs have led to increased machine uptime, which in turn increases production rates.

Chemetall continues its on-site work with CNH Fargo to improve sump maintenance, manage tramp oil leaks and removal of tramp oil, and provide ongoing operator training. By converting to Tech Cool 35052, Mr. Bratsch says CNH Fargo has greatly reduced the non-value-added activities that historically eroded its productivity. “We expect a lot from ourselves and our suppliers. Our agricultural customers demand high quality from our equipment, and we aim to always deliver,” he says.

Related Content

AFT's Semi-Synthetic Coolant Extends Sump Life

Advanced Cool 2200 provides high visibility while machining, keeping the machine and parts clean with no odor issues.

Read MoreConsiderations for Machining Coolant Care

Coolant care can be simply managed if you know where to pay attention and which hazards to look out for.

Read MoreJorgensen Introduces Sustainable Conveyor, Material Handling, Coolant, Filtration Solutions

IMTS 2024: Jorgensen Conveyer and Filtration Solutions announces a lineup for conveyor, material handling, coolant and filtration solutions, including the EcoFilter80 self-cleaning system, the PermaClean system and others.

Read MoreNew Coolant Designed for Automotive Parts Production

Choosing the right coolant is critical for productivity, economic efficiency and machining quality.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)