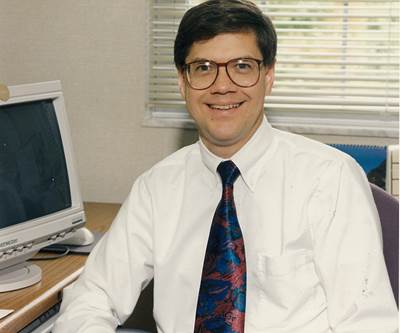

Mark Albert's Long-Running Monthly Column Marks Its End

My long string of monthly commentaries is coming to a close.

Share

As a 27-year-old writer who had been part of Modern Machine Shop’s staff for one year, I began writing a column titled “Mark: My Word.” Since its first appearance in the January 1981 issue, I have written 457 such columns. This one, however, is my last. That is enough.

For 38 years, I have never not been thinking about and searching for my next column topic. Sometimes an idea popped into my head on a late-night stroll or during a morning shower, and the column was finished a few hours later. Other times, an idea that had been kicking around in my mind for months or even years had to be coaxed out with difficulty, then labored over in rewrite after rewrite. Most often, I found something worthwhile to write about by simply monitoring the pulse of our industry. I visited shops, attended trade events and scanned product and news releases. What never varied was the pressure of a monthly deadline. Writing this column was a fixed part of my job.

No matter how easily this column came to fruition, however, the monthly task was always more than just “part of the job.” It was an opportunity to exercise the writer’s craft, to apply skills as best I could in a conscientious, purposeful manner. Wordsmithing, I wanted to believe, was somehow akin to blacksmithing, the ancient root of industrial metalworking. For me, this belief formed a primal bond with today’s machinist. Indeed, the image of hammer and anvil often seemed a fitting symbol for the effort of pounding out ideas and shaping them as words on paper.

At times, I saw this page as my attempt at the art of fine writing—a chance to be creative, to add a touch of literary grace to meaningful expression. Nevertheless, my primary intent was always to deliver value to the readers of this magazine. Mostly, this meant conveying useful insights into the evolving nature of machining and metalworking. Stirring the imagination or even evoking a smile was fine, too.

My unwavering intention was to be respectful. I have been deeply honored by the privilege of serving those who make a living in the manufacturing industry. I was also keenly aware that I was an observer of, not a participant in, the flux of daily life in a shop or plant. In many regards, my audience would always be smarter and more in touch than I. It was also clear to me that society and its policymakers rarely gave “our” industry the respect, esteem and support it deserved. My best response to this neglect was using this column to remind readers of the dignity, importance and value of this occupation. It is a vocation, truly a high calling, honorable and prestigious.

As regular as my column output has been over the years, I’m sure the quality was not as even. Some columns were surely forgettable. Far more, I hope, were memorable. Hearing that certain readers had tucked a piece into the lid of their tool chest or tacked it on the wall in a programming or engineering office was hugely gratifying. (I have my personal favorites, too, I admit.)

Most of all, I am grateful for every instance one of my columns had the attention of a reader.

Although this is my last “Mark: My Word” column, I will continue to write articles for MMS, at least for a while on a part-time basis, working mostly from home. I have not ruled out the possibility of making shop visits to get a story, take in a trade show or an out-of-town press event. But no more monthly commentaries. For me, enough is enough, mark my word.

Read Next

The Sign on the Wall When I First Met Mark Albert: “When In Doubt, Tell the Truth”

Not just writing, but writing with integrity, is the work and the craft to which Mark Albert gave his career.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=970;quality=90)