Making History with the Right Technology

An Acu-Rite digital readout has helped turn what is truly a legacy milling machine into one capable of making history—literally. The results will keep a restoration project afloat at a maritime museum in San Francisco.

Share

The USS Pampanito, a famous WWII submarine, is being restored and refurbished in an effort to return it to its original condition.

A passion for historical accuracy and authenticity is essential to individuals devoted to preserving important pieces of our national heritage. The donation of an Acu-Rite digital readout (DRO) to the San Francisco Maritime National Historical Park Association is aiding in this effort. The DRO, a gift of the Heidenhain Corp. and corporate parent of the Acu-Rite brand, has made an old Bridgeport milling machine capable of producing accurate copies of missing parts needed in the restoration of the USS Pampanito, a World War II submarine preserved by the Maritime Park Association.

The milling machine will also be used to repair original historic artifacts—items that embody the significance and authenticity of this unique museum display. In this case, the preserved submarine is also a memorial to the men and women of the armed forces who served in World War II. The Pampanito was well known as having made six patrols in the Pacific during the war. It is currently undergoing important restoration and replication projects to bring it as reasonably close to its original operational condition as when it sailed in the summer of 1945.

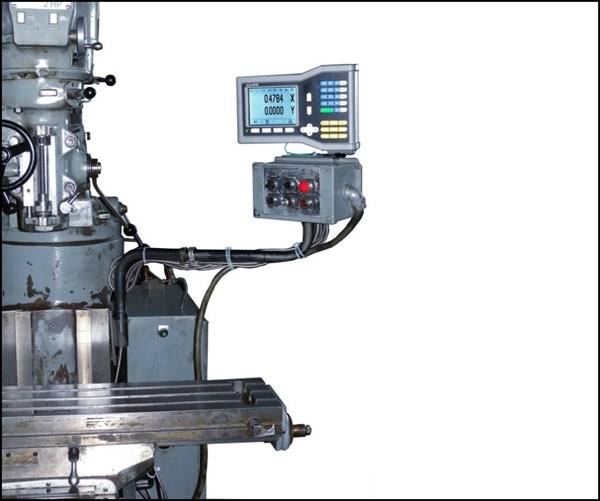

The submarine has been docked and open to the public at Fisherman’s Wharf since 1981, where it educates approximately 4,000 students in day and overnight programs annually, and 100,000 visitors a year who tour the boat. Maintaining the submarine as a non-profit is a huge challenge, and the Maritime Park Association relies heavily on donations to further its goals of bringing maritime history to life, offer future generations its important teachings, as well as honor the men that served there. To that end, when Heidenhain staff learned that the project received an old Bridgeport mill from a local machine shop as a donation, and that the 1980 digital readout on it was broken and obsolete, they approved the donation of an Acu-Rite VUE 2 digital readout kit. The VUE came with two SENC 150 scales and accompanying brackets.

With a new DRO and accompanying scales, this milling machine will be "making history" as it produces historically accurate copies of parts for the USS Pampanito.

“We were very happy that someone at Heidenhain/Acu-Rite took the time to understand our mission and donate this DRO,” says Rich Pekelney, one of the Maritime Park Association’s trustees and volunteers. “I’ve been doing hands-on restoration like this for 23 years, and our small machine shop is a vital part of our project.

“With our refurbished mill, we expect to be able to do many things ourselves now,” Mr. Pekelney explains. “For example, we recently acquired an old five-inch deck gun that would have been used here during WWII but is missing parts. Now we can make them so that this piece can be showcased appropriately. Or we can also make the mounting brackets that are needed so that we can hang the bunk beds as they were in 1945, and so on.”

The well-used Bridgeport mill received by the Maritime Park Association is a classic 42-inch table type, not unlike many of the legacy machines that shops want to save for one-offs or utility applications such as repair work or fixture making.

“We know that DROs have great value on any manual milling machine in order to do accurate work, particularly on older ones which might have a little more side-play or backlash, so this DRO is very much appreciated,” Mr. Pekelney says. “We were familiar with Acu-Rite DROs and our machinists have experience with them. We know they are easy to use and reliable products.

“We found the DRO quite easy to retrofit onto the machine, and were thrilled that the mounting brackets and all were included in the kit. Overall, we are very grateful that Acu-Rite recognized the importance of and for participating in this project to preserve this part of our national history.”

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)