Machining is the Hero

It was a pleasure to visit Lockheed Martin to learn more about the F-35 fighter aircraft, because CNC machining was the hero of the story I got to tell about the plane.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

It was a pleasure to visit Lockheed Martin to learn more about the F-35 fighter aircraft, because CNC machining was the hero of the story I got to tell about the plane. Specifically, precision machining of composites gives this plane low observability at a low cost, and that advantage encouraged various allied countries to help the United States taxpayers pay for this plane.

Of course, it is more accurate to say that the people behind the CNC machining are this story’s heroes — people ranging the machine-tool and tooling technology developers to the people who put the equipment to use. In almost any production facility, these are the people who quietly overcome technical challenges, rarely getting (or seeking) recognition for the work.

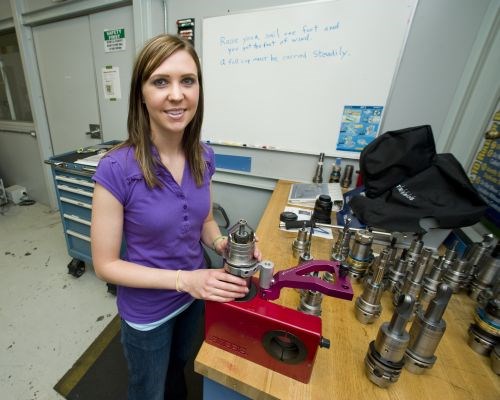

I got to meet some of those people during my visit. Jamie Smith, shown at left, is a Lockheed Martin engineer who (along with Rick Luepke) led the development of a toolholding device that made countersink machining more accurate for the company. Rick Denny, at right, is a technical lead who worked to get acceptable cutting tool performance in the challenging material. Read their story here.

.png;maxWidth=300;quality=90)