Machining And Operator Productivity Get A Boost From Mastercam

This magnetic workholding manufacturer wanted an advanced CAM package to go along with some new machine tools it recently purchased. Mastercam not only kept these machines operating to their full potential, but also breathed new life into the shop’s older CNC equipment.

Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Faced with global competition, today’s manufacturers need to use technology in a way that allows them to stay competitive or to gain a competitive advantage. These strategies often involve the purchase of new machine tools and other equipment. However, while the latest machine tools can do wonders for productivity, CAD/CAM software packages shouldn’t be overlooked.

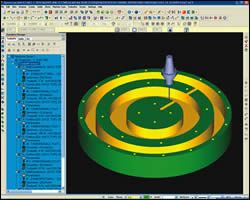

Rich Laprade, manufacturing engineer at Walker Magnetics Group, can attest to this fact. As part of an integrated solution to some of its manufacturing problems, the Worcester, Massachusetts-based manufacturer of magnetic workholding equipment purchased CNC Software’s Mastercam X2 CAD/CAM package. In addition to keeping newer machines running at their full potential, the software breathed new life into older equipment by generating more efficient tool paths than the company’s previous CAM package.

Walker Magnetics Group began in 1896 when Oakley S. Walker invented the electromagnetic chuck and founded the O.S. Walker Company. Throughout the next century, the company expanded to provide custom design and manufacturing of a wide range of permanent, electromagnetic and electro-permanent magnet products and systems for industrial applications. Today, Walker delivers products to more than 190 countries worldwide and has manufacturing and research and development capabilities in North America, Europe and Asia.

The company has three primary product families: magnetic workholding, magnetic work lifting and magnetic separation. At its manufacturing facilities, the company does everything from basic machining operations such as milling, turning and drilling to fabrication of sheet metal and the design and manufacture of electrical control devices. Products range from a 3-inch-diameter magnetic driver for a lathe to a 100-inch-diameter magnet used in scrap yards.

As part of an effort to stay abreast of the latest technology, the company purchased a new vertical machining center and a new turning center in Chicago at IMTS 2006. Rather than trying to apply its old CAM program to the newer machines, the company also sought to purchase an up-to-date software package. It eventually settled on Mastercam version X2 and began using the software for milling and turning within a month.

According to Mr. Laprade, even operators with very little programming experience are able to become productive problem solvers with minimal training. “This is because of the software’s inherent user-friendliness,” Mr. Laprade says. “After installing it in November 2006, we had a single person doing all of the programming. Now, we have four people capable of programming.”

Much of the company’s work involves creating deep cavities that hold electromagnetic or energizing coils. “One of the things that we’ve been pleasantly surprised about is how Mastercam can handle that kind of deep-pocketing routine, whether it’s in a turning situation or a vertical milling situation,” Mr. Laprade says.

In another application, the software has enabled operators to minimize the number of tools used in turning operations. They’ve been able to use one tool to perform multiple functions, which was impossible with their previous CAM software. In the past, for example, a necking operation would have required a tool change. Now, the operation can be performed with a single tool because the tool paths that the software uses for the application seamlessly integrate into the program, Mr. Laprade explains.

The company often produces prototype or one-off products, so getting an accurate cost quote is important. The software has proved to be beneficial here, as well. Its “verify” feature provides an envelope for planning and scheduling tools. “If it tells me that the run time is 23 minutes, and I’ve got eight parts to do, we know when and where we can slot that job,” Mr. Laprade says. “It also becomes a planning tool.”

The program has also enabled the company to take advantage of current tooling technology. Its tool library provides users with knowledge about how specific tools and inserts will perform in the cut, allowing them to project production time. In addition, the library allows the company to pick a specific vendor as a solution provider.

“If we can narrow our tool selection to a good, reliable family of tools, as opposed to having many different tools from different vendors, we’re much better off,” Mr. Laprade says. “That’s because now we know the capability of the tooling and can spread that capability across a wider spectrum of machines.”

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)