Published

Machine Tool Probing Leads to Prevention-Based Mfr. and Predictive Maintenance

A white paper from a supplier of precision measurement services states the case for leveraging on-machine probing into a strategy for reducing waste in a manufacturing process. Improved productivity and higher profits are the ultimate goal.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Morley Machine Tool Alignment in Milton, Washington, provides machine tool calibration services, helps shops implement on-machine probing, does machine tool repair, conducts metrology engineering studies and offers other services to manufacturers. This multi-pronged business model makes the company aware of the interaction between its customers’ approach to process planning, shop operations, inspection and maintenance. These insights are reflected in a white paper authored by Stephen E. Smith, the company’s chief operations officer.

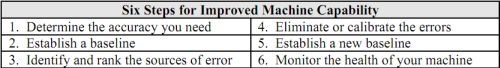

Titled “Improve Machines and Processes: Improve Profits,” the white paper outlines how machine tool probing systems provide the basis for prevention-based manufacturing. Prevention-base manufacturing is characterized as a method to reduce or eliminate non-value-added activities that devour resources in the later phases of the production or product life cycle.

The paper also discusses the role of probing systems in establishing an effective predictive maintenance system. Probing enables a shop to establish a machine’s performance capabilities. This step is key to characterizing machine tool accuracy; picking the right machine for the right job based on part tolerance requirements; and spotting deterioration in machine performance before it begins to affect quality.