Launching an Apprenticeship Program for $130

This shop uses an inexpensive plug-in for a website-hosting platform to manage its custom, in-house apprenticeship program.

Share

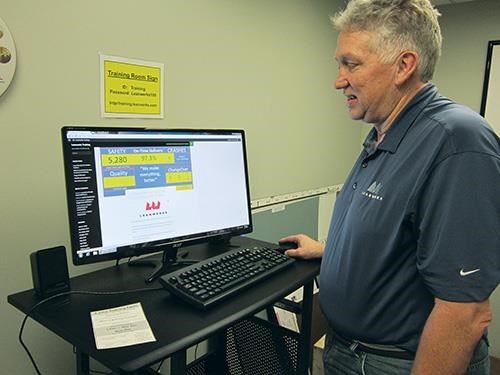

Paul Harbath, director of quality and continuous improvement for LeanWerks, has been key to helping develop the lessons for the shop’s Technical Excellence Training (TExT) program and administrating it.

LeanWerks calls it “TeXT.” TeXT stands for Technical Excellence Training program, an in-house apprenticeship program the shop developed to cultivate its own talent and provide new hires with a clear pathway leading to a machining career.

To manage it, the shop used WordPress to create a TExT “training website,” and then purchased a plug-in called LearnDash, which effectively turns WordPress into an online learning management system. The one-time cost for the LearnDash license was a mere $130.

As described in this article, many training lessons in the TeXT program include instructional video taken of actual LeanWerks shopfloor processes and practices to clearly outline the steps required to complete a given task safely and effectively. To date, the shop has produced more than 130 such videos for its TExT program. The article mentioned above includes an example of a training video LeanWerks produced explaining how to properly fill out first- and final-article inspection reports for a given job.

Related Content

-

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

-

Manufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

-

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.