Inside Ford Sharonville Transmission: Producing 19 Million Gears a Year

The men and women at Ford Sharonville have turned the art of gear making into a science. They make them precisely. And they make plenty of them.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreThe Ford Livonia Transmission Plant is 5 miles due east of the Automotive Design & Production office in Plymouth, Michigan.

The Ford Van Dyke Plant is 45 miles northeast of the office, located in Sterling Heights, Michigan.

The Ford Sharonville Transmission Plant is 250 miles south of the office, in Sharonville, Ohio.

So when we contact Ford and say that we want to learn more about gear making, they suggest … yes, that we go to Sharonville.

Which naturally leads to the question of why?

Well, the first answer might have something to do with the level of output at the facility. As in, approximately 19,000,000 gears produced each year. That, says Tim Boes, plant manager at Sharonville, is on the order of 180,000 gears per day. There are some 1,500 people working in the plant, and while sometimes there is a distinction between “working” and working, know well that these people are giving it their best seven days a week, around the clock. At Sharonville, they’re running a four-crew operation, which means 12-hour shifts, 5 to 5, with three shifts one week and four the next. Repeat.

Since the plant opened in 1958 (they were building three-speed transmissions back then), they’ve produced over 45 million transmissions (and by the time you read this, that number will have steadily grown).

The plant is 2,415,000 square feet under roof. Which means you could put 42 football fields in there. And as Tom O’Connor, manufacturing engineering, new program leader, points out, “It’s full out there.” Full of a wide range of machine tools and equipment. Mind you, this is not a place where you have to snake your way through rows of dirty, greasy machines that seem to have been installed perhaps back in 1958 and not sorted since 1959. No, Sharonville is orderly and organized, which is in keeping with the demands of a place where the metrics that matter are measured in microns.

Consider this: In one station on the floor, they are bore honing the ID of a gear. There are three stages in the operation: roughing, semifinishing and finishing. The roughing operation removes 60 to 80 microns of material. The semifinishing removes 20. And finishing is on the order of one to two microns. Eighty microns is the approximate diameter of a human hair. So it is hard to imagine what 1/80 of that might be, but there they are, working toward it in mass production.

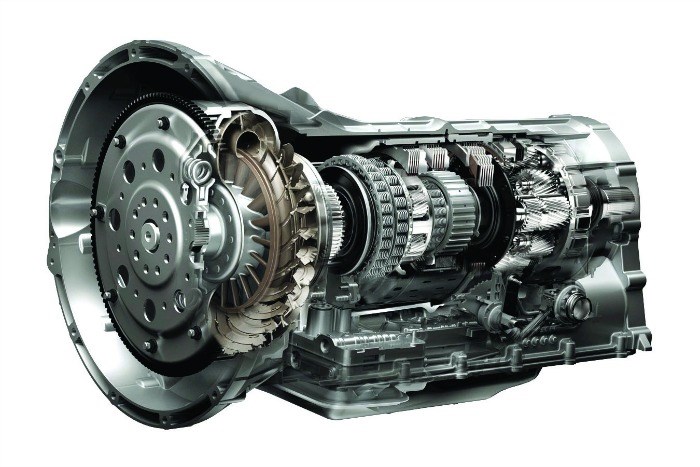

Today they are fully producing—including all machining, heat treating, pressworking, assembling and testing—two transmissions. There is the 5R110W transmission for the Super Duty and Econoline. There’s the 6R140 for the Super Duty and the medium-duty chassis truck.

In addition, they are supplying other Ford transmission plants—yes, as in Van Dyke and Livonia—with a wide array of gears and transmission components. There are converters for the 4R75E (Econoline); carriers for the 6R80 (F-Series, Expedition, Navigator, Raptor SVT, Mustang); and carriers and gears for the GF35 (Fusion, Escape, Explorer, Edge), 4F27E (Transit), and 6F50/55 (Edge, Flex, MKX, Taurus, MKS, MKT, Explorer).

As Mr. Boes puts it, “We basically support every single vehicle that Ford North America makes and sells except for the Fiesta and the Focus. We either make the gears or the transmissions or other components.” And he adds with a measure of serious conviction in his voice: “This is something we don’t take lightly. It is a big responsibility for us to support all that.” They know it. So they deliver.

When we go out on the floor, Mr. Boes says that there are “2,025 different machines that actually make something.” He’s “not counting automation and ancillary stuff.”

There are well organized machines from Gleason-Pfauter, Escofier, Felsomat, Reishauer, Heller, ITW, Marposs and more. They are hobbing, rolling, loading, grinding, and milling. They are heat treating and vacuum carburizing and peening.

And they are checking. Every step of the way.

One of the things that stands out while walking the floor and talking to the women and men who are responsible for making the gears and assemblies is the dedication to quality. While it is fairly common to assume that, as the old Ford slogan had it, “Quality is Job One,” oftentimes the assumption or expectation that it is being addressed leads to something that isn’t there. Yet at every station we stop at, the Sharonville personnel point out the sensors, cameras, torque monitors, RFID tags, gaging stations and other devices used to check the quality of the parts being produced, checks that occur both on the floor as well as in the metrology lab, checks that are completed to schedule because if the checks aren’t made, if there isn’t traceability, then the gears and assemblies aren’t going to progress through the system. It must be done. Regularly. Relentlessly.

What’s also notable is that these women and men explain that there is also regular “challenging” of the tools that they’re using to ensure that the dimensions are right and that the components are properly assembled. They run through “ringers” on a regular basis to make sure that the results they are getting from the measuring tools are accurate.

“Every single operation we have has a batch-hold,” Mr. Boes says. Selected parts from a batch, which vary in quantity but are generally on the order of 200 to 300 pieces, are taken for measurement. Only after that has been completed and only if the results are within the tolerance band do parts progress to the next step.

They have total traceability so that, Mr. Boes says, “If we get any field issue, we know exactly what happened to the gear and when it happened, all the way back to the gear blanks coming in the plant.”

This focus on making sure that they are making things right has been acknowledged by the Ford leadership team. In March, the Ford 2013 North American President’s Quality Awards were presented, and Sharonville was named “Best Powertrain Transmission Plant.” They were also presented with the award for 2012. And for 2009, 2007 and 2006.

One might think that, given the nature of making 180,000 items per day, the most efficient approach would be to have fairly fixed automation. That was once the case at Sharonville. Mr. O’Conner says, “We’ve walked away from the old traditional fixed automation with multiple hobs or grinders plugged into the same automation with big, massive accumulators, gravity-feeding the machines. With the new concept, we can flex from part A to B, product C to product D, as we need to.”

Kenneth N. Lowe, Gear & Carrier manufacturing supervisor, Ford Global Production Engineering, says that this isn’t even a cellular approach, as that was deemed to be too restrictive in terms of having the sort of flexibility that the facility needs in order to address the needs of its customers. (Realize that during any given month, the sales of, say, a Ford Fusion rises and falls, as is the case of a Mustang or any of the other vehicles that Sharonville supports.) “By having independent machines,” he says, we are able to use the capacity as needed.” To be sure, they are running the machines in a sequential pattern, and the machines are logically grouped. But what they are looking for is a means to achieve flexibility without sacrificing production.

One of the things that Mr. Lowe says is different at Sharonville compared with the plants of other transmission manufacturers is that they roll gears in cases where the tolerances permit; they don’t shave. With rolling, the final geometry is put into the green gear with a set of rolling dies prior to heat treating. This means that the gears must be designed such that there is accommodation made so the hobbed geometry provides a place for the metal to be moved during the rolling process and so distortion (a consequence of heat treating) doesn't affect gear performance.

Why roll? Mr. Lowe says that it is very economical. “A set of rolling dies lasts for about a million gears.” So at a place like Sharonville, where a million gears are made in a matter of weeks, that’s important.

Of course, nowadays, gear grinding is more a matter of course. “Whenever we have a new program,” Mr. Lowe says, “we ask Product whether we can roll. It is an NVH [noise, vibration, harshness]-driven decision.”

That is, as vehicles have become increasingly quiet, gear noise that can be generated by the transmission has become increasingly noticeable. This means that it is typically required that gears are ground rather than rolled, because of the precision that is achieved through grinding. “Most of our gears, because of NVH requirements, have to be ground because the specification is so much tighter,” Mr. Boes says. “We’re dealing with a few microns rather than 20 or 30.” Twenty microns: a quarter of the diameter of a human hair.

Which brings us back to the beginning, to why Sharonville rather than Livonia or Van Dyke.

It’s because Sharonville is Ford’s Gear Center of Excellence. The company wanted to create a knowledge base and the requisite technical strength in one location so that there would be a thoroughgoing capability and understanding of what it takes to produce gears and transmissions.

“Making gears is a very complex business,” Mr. Boes says with a smile. It is hard to imagine a greater case of understatement.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)