New jobs deserve a fresh look, despite the instinctive temptation to turn immediately toward tried and true methods and equipment. Zack Hilton of River City Manufacturing and Machine Company (RCMM) says that approach paid off in revamping a slot-finishing operation in hardened tool steel. That job also exemplified the benefits of minimizing contact area between insert and workpiece in milling applications that involve slots, hardened materials and/or long reaches.

RCMM’s application involved all three, prompting a representative from Ingersoll Cutting Tools (Rockford, Illinois) to recommend that manufacturer’s Form-MasterV backdraft cutter. By engaging a smaller portion of the insert at higher feeds and speeds than the previous tool, the cutter provided an 80-percent cycle-time reduction, longer-lasting edges and more predictable edge wear. Since the tool swap, the shop has also been confident enough to run the part completely unattended. “The cutter paid for itself after the first piece,” Mr. Hilton says.

RCMM opened its doors in 1989 as a two-man shop based in what used to be a livestock building on a small hobby farm in Winona, Minnesota. Mostly manual equipment gave way to CNC machining in the late ‘90s, and today, the company offers milling, turning, waterjet cutting, heat treating, drafting and more from its modern, 10,000-square-foot facility. The 20-man operation runs 20 hours a day, five days a week, producing mostly repeat orders in small lots for tools, molds and various engine and machine parts.

The slot mentioned above is part of a component that goes into a slide mechanism on a chain-fabricating machine. Measuring 12 inches long, 4.322 inches deep and 2.724 inches wide—nearly twice as deep as wide—it is machined in S-7 tool steel hardened to 54-56 HRc. The finish-milling operation, performed to correct for any distortion resulting from heat treating, had to produce a mirror finish. It required removing 0.02 inch of material from both sides to tolerances of +0.002/-0.000 inch.

Mr. Hilton first reached for what had become his “go-to” cutter for most milling operations: Ingersoll’s Hi-PosQuad indexable end mill. However, despite having achieved a great deal of success with this tool on a variety of other jobs, he found that the tool’s insert edges would rupture unpredictably while engaged in the deep slot. Having to stop and change inserts midway through the cut would cause a production bottleneck on a part with good reorder potential. This would also leave track marks on a surface with a stringent finish requirement. Rather than settling for a familiar but less-than-efficient process, he decided to look for a new tool.

Fortunately, the Hi-PosQuad is part of Ingersoll’s “Top-On” modular tool family. As such, changing tools would be a matter of screwing a different tip onto the existing five-inch, solid carbide, threaded shank. Faced with a choice of 50 different styles, Mr. Hilton consulted Ondrej Lubinski, an Ingersoll field rep who visits RCMM almost weekly.

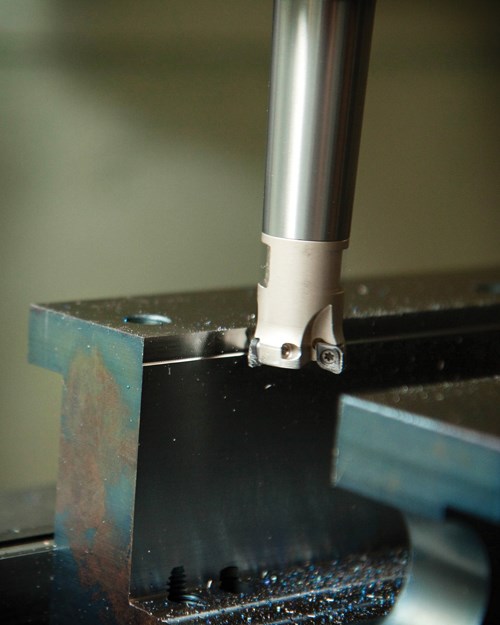

Mr. Lubinski closely examined the application and took particular note of the long reach involved. This could make the setup especially vulnerable to lateral cutting forces. In addition to creating difficulties with meeting the close tolerances required for the sides and bottom of the slot, the resulting chatter and excessive impact load could fracture the insert or even the shank itself. The hardened workpiece material would exacerbate the situation by leading to even higher cutting forces. “In a case like this, the strategy should be to minimize the contact area between insert and workpiece, feed fast, and take very light cuts to avoid overloading any part of the system—tool, workpiece, fixture or machine,” he says.

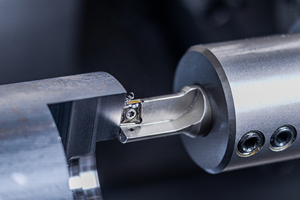

With that in mind, Mr. Lubinski and Mr. Hilton evaluated their options and settled on the Form-MasterV. Unlike the Hi-PosQuad’s 90-degree inserts, this tool’s inserts feature a rounded, rhombic shape. According to the company, this shape provides backdraft on the side and bottom of the cutter once the inserts are clamped in place. As a result, only the acute-angle radius and small wiper area actually touch the workpiece and create the chip, as opposed to the entire side of the insert. Also, the inserts are double-sided, so each features four usable edges. Running this cutter at increased feeds and speeds would offset the reduction in cutting surface area, the two men reasoned. That way, the slot could be finished just as fast without overloading the insert.

The first trial proved them right. They opted to remove the 0.02 inch of material on each side of the slot in two passes: one to eliminate the “extra-hard crust characteristic of a heat-treated part,” as Mr. Hilton describes it, and the second to achieve exact size and finish. RCMM had run the previous 1-inch, Hi-PosQuad end mill at 1,400 rpm, 18 ipm and a 0.005-inch depth of cut. With the new tool, the shop boosted those parameters to 2,600 rpm, 60 ipm and 0.01-inch depth of cut, respectively. As a result, cycle time decreased from 20 hours to 4. More importantly, the new inserts lasted through two full parts, and edge wear was gradual and predictable as opposed to the sudden failure of the previous tool.

When the process went from trial to operational, Mr. Hilton cut back on the settings for peace of mind and more process security. For instance, although the new cutter could handle a 0.01-inch cutting depth, he would run it somewhere between that and the previous 0.005 inch. Still, edge life improved by 4 to 1 on average, and throughput improved 2 to 1.

More recently, he has run the job at more aggressive cutting parameters with no loss of edge life or process security. He has also been running the parts two at a time, often overnight and completely unattended. “We would have been happy with just the edge life benefit,” he notes. “The throughput gain—under lights-out conditions—is icing on the cake.”

Gains in the slot-finishing operation notwithstanding, RCMM still uses the Hi-PosQuad as its mainstay cutter, even on other long-reach applications using 8-inch shanks. However, most of this work consists of rough and finish milling unhardened metals, not hardened tool steel. “It’s a fine bread-and-butter cutter,” Mr. Hilton says about the Hi-PosQuad. “We simply found a better fit for a particular finishing operation. It’s important to look at each new job with new eyes. What’s most comfortable might not be what’s best.”

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)