Until the economy and the coal industry strengthen significantly, simple economics dictate that companies will rebuild hydraulic components on construction and earth-moving machinery rather than buy new ones, says Mike Harbin, manager of Whayne Supply’s Power Rebuild Center. Normally, this would mean a significant increase in profit for the Caterpillar dealer; however, the hone it was using to resurface scratched and rusted cylinder barrels lacked the ability to remove metal and completely rebuild the cylinders. To avoid outsourcing this work, Whayne agreed to use an all-electric HTA tube honing system from Sunnen Products Company (Saint Louis, Missouri) as part of a beta test. Eventually, the hone would prove to be just what the shop needed to produce quality parts.

Since 1985, Whayne Supply has rebuilt more than 400 complete machines. The Corbin, Kentucky facility, which is one of 14 company locations, employs 200 of the approximately 1,300-person workforce. It is also one of two locations where the Cat-certified rebuilder processes exchange/re-sell goods (the other location is in Louisville, Kentucky). The Corbin hydraulics shop employs eight cylinder technicians, three full-time machinists, three pump experts, a foreman and a service coordinator.

Each Caterpillar machine averages four hydraulic cylinders. “We have customers who are tearing down machines in the field and completely rebuilding them,” Mr. Harbin says. To stay on top of this trend, the Corbin facility added a machine shop in 2009 that included two vertical mills, two lathes, a drill press, a rotary surface grinder, welders and saws. The shop’s five cylinder service bays include one for suspension cylinders, one for lift cylinders on small loaders and three for high-force cylinders. In these bays, shop employees can replace the barrel, rod, rod eyes, head/seal areas, hydraulic lines

and connections, or custom fabricate new cylinders to spec,” says Michael Carter, service coordinator.

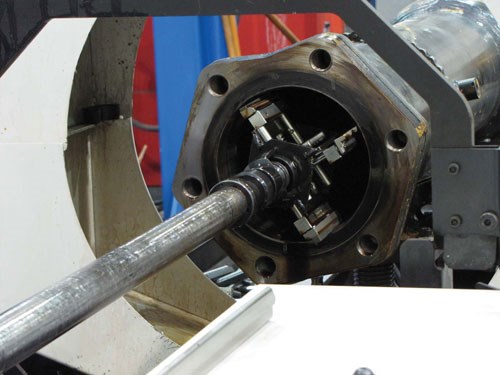

Even with a well-equipped machine shop, one critical piece was missing to completely salvage cylinders in-house. The shop’s original hone consisted of a drill motor on a sliding carriage, and it lacked the power, capacity and rigidity needed for doing serious work, Mr. Carter says. “It could produce a surface finish, but not remove metal,” he says. Whayne brought in the HTA cylinder hone in 2009 as part of a beta test of Sunnen’s new all-electric machine design and later purchased the machine with a 12-foot (4-meter) part capacity.

The new hone can accommodate parts weighing as much as 8,000 pounds (3,629 kg) with inner diameters (IDs) ranging from 2.5 to 21 inches (63.5 to 533 mm). It is designed for resurfacing and repair work that requires light-duty stock removal ranging to 0.030 inches (0.76 mm). Standard models are sized for 6-foot (2-meter) and 12-foot (4-meter) part lengths, and custom lengths are also available.

Whayne uses both roughing and finishing abrasives to remove scratches and rust and impart a specific crosshatch surface finish on the barrel bore. The shop can increase the cylinder bore diameter to 0.254 mm (0.010 inch) in a relatively short time, Mr. Carter says, removing rust and all but the worst scratches and remaining within Cat-machine specifications. “Our old hone simply could not do this,” he says.

The HTA is equipped with a Siemens drive and PLC with touchscreen human machine interface (HMI) for setting machine parameters such as stroke reversal point, spindle/stroking speed and crosshatch angle calculation. According to Sunnen, the touchscreen control provides a safer working environment and reduces operator fatigue. The control features a load meter to determine areas of bore tightness, and can dwell the tool in multiple areas to correct part geometry. The controlled crosshatch pattern contributes to better quality parts because the honed surface can retain oil or grease, ensuring proper lubrication and ring seal with pistons in cylinders.

The shop hones cylinders ranging from 2.5 to 17 inches (63.5 to 432 millimeters) in diameter and 6 inches to more than 21 feet (152 millimeters to more than 6.4 meters) in length. These parts are much longer than the 12-foot hone is intended to machine. To accommodate long cylinders, the shop created a table with an adjustable-height V-block to support parts that overhang the machine. “We have used a drive shaft ranging to 21-feet long on the machine, and we can hone from both ends of the part if need be,” Mr. Carter says. Cycle time for most barrels is about 30 minutes, which includes setup, honing and washing the part.

Given that refinishing cylinders can save CAT machine users as much as 80 percent of the cost of a new barrel, this previously-outsourced work has proven more than enough to occupy the new hone. In 2011 alone, the shop processed 1,000 cylinders. The extra workload has not only boosted revenue, but also required the addition of five new employees to keep up. “During the summer, we may have a hundred or more cylinders outside our shop waiting to be rebuilt because our indoor storage is full,” Mr. Carter says. “We scrapped a lot of hydraulic barrels or sent them out to other shops prior to acquiring this machine. Now, we can salvage a cylinder with honing, and the cost and time for the customer is a fraction of replacement. In the current economy, customers appreciate this.”

.png;maxWidth=45)

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)