Friction Stir Welding for SLS Rocket

Esab has developed what is said to be the largest welding machine of its type in history for rocket fuel tank structures.

Share

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

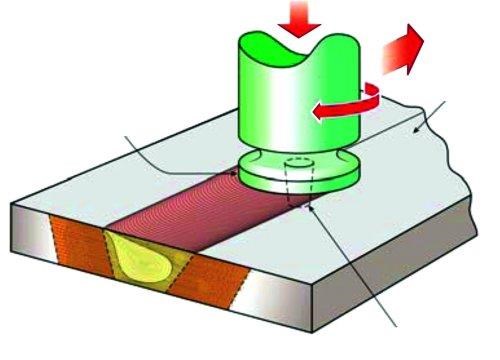

During friction stir welding, friction at the shoulder of the tool (shown in green) creates heat to soften the material without melting it. Meanwhile, the profiled pin buries itself in the softened material, stirring it as it moves forward.

The SLS will be the largest U.S. rocket ever built. It will measure 384 feet in total length (200 feet taller than the entire space shuttle rocket assembly) and weigh 6.5 million pounds. The construction of an assembly of this magnitude requires entirely new ways to fabricate, assemble, and weld the main fuel tank structures. Engineers from Esab have worked with Boeing and NASA for more than a year to develop the new Vertical Assembly Center (VAC), a giant orbital welding system that is capable of supporting the huge rocket fuel tank while circumferentially welding its sections together with the friction stir process. Esab’s construction of the VAC is said to be the largest welding machine of its type in history.

The VAC is being designed, engineered, and built at the Esab’s Laxa, Sweden facility and is supported by Esab’s North American Automation Division. The vertical tower assembly is being built in the United States using U.S. steel and component materials.

Friction stir welding uses a spinning tool with a great deal of pressure and torque to mix metals together without melting them. This allows users to fuse together hi-tech alloys that are difficult or impossible to join with conventional welding techniques. Read this article to learn more.

.png;maxWidth=150)