Five-Axis Machines Give Shop Advantages

This company purchased its first five-axis machine, and since then it has added four more. The rapid growth of this business segment has generated plans for retiring older three- and four-axis machines in favor of total five-axis capability.

Share

Tom Mullen started TNT EDM (Plymouth, Michigan) in 1978 in a 3,600-square-foot building with four employees. As the company’s president, Mr. Mullen has managed its growth to today’s 77,000- (and growing) square-foot complex in which 40 people tackle applications in an atmosphere that resembles an executive office more than a machine shop.

The design of the TNT facility reflects Mr. Mullen’s unorthodox style. The offices and the manufacturing complex meld seamlessly together. Select natural woods and polished granite are everywhere. Manufacturing bays are entered through maple-trimmed archways off corridors featuring granite flooring. Chips are quickly removed; coolant and oil smells are undetectable; and, once completed, parts are immediately expedited. The result is an atmosphere reflective of quality and precision that never fails to impress customers—or employees. “To be successful requires three things: the right customers, the right people and the right machines,” Mr. Mullen states. “We designed our facility to demonstrate excellence to our customers and to provide a working environment where our people would be extremely comfortable.”

At the start, TNT was strictly an EDM shop serving the plastics injection molding industry. “I began with four sinker EDM machines,” says Mr. Mullen, “and quickly expanded to wire EDM as well. Initially, we added machining capability in order to bring in more EDM work. But when we added five-axis machining 2 years ago, we were extremely impressed with the capabilities, and now we’re taking on projects that involve strictly machining.”

The pursuit of excellence in difficult applications is in line with Mr. Mullen’s business philosophy. “Ten years ago, we did work for 50 customers,” he says. “Now, we’ve made a conscious effort to winnow that number down to about ten, four of which are responsible for the bulk of our work. We wanted to eliminate distractions and do the best work possible for our most valued and loyal customers. They, in turn, send us some of their most challenging jobs.” The applications Mr. Mullen refers to include forging die components; complex automotive parts, including powder metal components; molds for plastics manufacturers; and impeller and airfoil parts for the aviation industry.

In 2000, the company purchased its first five-axis machine, and since then it has added four more. The rapid growth of this business segment has generated plans for retiring older three- and four-axis machines in favor of total five-axis capability.

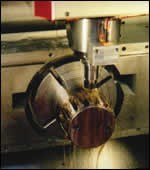

All five-axis work is accomplished on five C Series machining centers from Hermle—four C600U models and one C800U. “When we bought our first machine, we didn’t have much experience, so we sought some outside advice,” Mr. Mullen says. After looking at the kind of work we were considering, Hermle was recommended for the flexibility inherent in the design and its ability to hold very tight tolerances in hard materials. One hundred percent of the work we do is complex; 90 percent of the machining is hard machining.”

Leon Carpenter, project manager and programmer, is a 9-year TNT veteran with experience in every aspect of machining. “The things that keep us sold on the Hermle machines are the Heindenhein control and the versatility of the machine itself,” he says. “The control has easy-to-learn functions for tilt axis machining and for simultaneous machining. It also has touch probe cycles that allow me to check the part before I take it off the machine. In combination with the quick tool changes and the ability of the A axis to rotate 110 degrees in both directions, the Hermle machine can minimize needless air time.”

Mr. Carpenter finds that the true value of five-axis machining goes beyond the ability to produce five-axis parts. By looking at the bigger picture, he has been able to define considerable savings in time and money by producing conventional three- and four-axis parts on a five-axis machine. “When you’re involved in hard machining, tooling is one of your greatest expenses,” Mr. Carpenter says. “The complexity of the parts we make means that we have to maximize tool life across the board. With a five-axis machine, better accuracy and the ability to optimize cutter lengths are essential. When you’re working in tool steel, that’s 52-62 R.”

Another way the company prolongs tool life is by operating at lower speeds. Spindles on the five-axis machines are capable of 16,000 rpm, but the company runs a standard 12,000 rpm. “Reasonable speed combined with a rigid spindle is a big plus in maintaining accuracy, avoiding tool failure and extending tool life,” he says.

“Without a doubt, the best reason for any shop to put a three- or four-axis job on a five-axis machine is the savings in fixturing and setup,” Mr. Carpenter continues. “Because the machine is versatile enough to approach the part from multiple sides and angles, you save a tremendous amount of operator hours and can generally get by with a more simple fixture. For instance, we do a die for an automobile connecting rod. Using a magnetic table, we can set up two blanks and literally run the parts overnight. When you’re doing limited runs of highly sophisticated parts, that kind of protocol can result in real savings.

“There’s no reason to buy anything but five-axis machines. I’d advise any shop that can afford them to go exclusively five-axis.”

Mr. Mullen sees another reason for maximizing machine versatility: “When I look at the work we’re doing today and compare it to where we were 5 years ago, it becomes obvious that parts are getting more complex. In addition, materials continue to get harder to machine. Obviously, if we’re going to continue to grow and maintain our high standard, we can’t rely on what worked yesterday. We need the machines that will take us into tomorrow, and for us, that means Hermle Machine.”

Read Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)