Fade Away or Burn Out?

Roll into the cut by following an arc that curves in the same direction as the tool rotation.

Share

Roll into the cut by following an arc that curves in the same direction as the tool rotation.

This keeps the chip thin at the end of each cutting edge pass.

“It’s better to burn out than fade away.” Both Neil Young and Def Leppard sang this. Neither of them could have been talking about cutting tools.

Shops want their cutting tools to “fade away.” That is, they want them to go through gradual, predictable wear. They don’t want them “burning out” in the form of a sudden, surprising failure. Even so, shops routinely (and unknowingly) subject tools to brief moments of intense strain that make the burnout a danger.

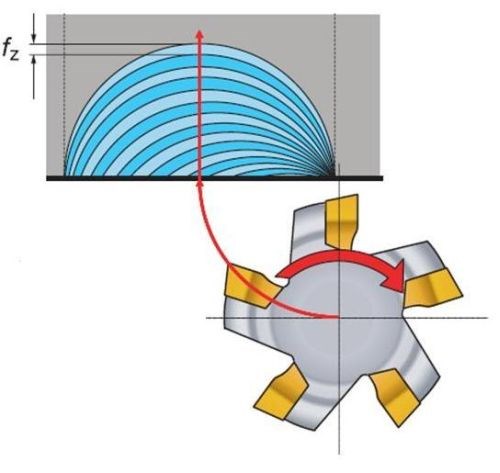

An example can be found in the way end mills often enter the material. Climb milling helps a carbide tool by enabling the chip thickness to proceed from thick to thin with each cutting edge pass—relaxing the load on the cutting edge gradually so there is no “springback” at the end of every pass. However, when the tool enters the material in a straight line, there is a brief period during which the full thick-to-thin progression has not yet been realized. During this period, the cutting edges are springing. Tests conducted by Sandvik Coromant show that just this brief span of time can cost the tool most of its potential life

The cutting tool maker offers this solution: “Roll” into the material. Feed the tool along an arc that keeps each cutting edge experiencing thick-to-thin chip formation from the very beginning.

The technique is one of the recommendations given in this article: Let the Tool Path Help the Tool.

.jpg;maxWidth=300;quality=90)