Face Drivers Cut Change-Over Time

In various applications, mechanical face drivers provide the flexibility to lower cycle times. Capable of being used to turn both small and large parts, they permit heavy and interrupted cuts.

Share

In various applications, mechanical face drivers provide the flexibility to lower cycle times. Capable of being used to turn both small and large parts, they permit heavy and interrupted cuts.

One benefit of face drivers is their ability to allow complete turning of a part in one operation, says manufacturer LMC Workholding (Logansport, Indiana). Appropriate applications include automotive transmission parts, crankshafts, cam shafts, pinion gears, electric motor shafts and axles with diameters as large as 36 inches.

Recently, a Hudson, Wisconsin, gear manufacturer discovered that it could keep up with the increasing demand for turned parts with LMC Workholding’s Neidlein face drivers while addressing TIR issues. Using these face drivers, United Gear & Assembly, Inc. was able to accommodate customer needs and lower scrap rates as well. The company says the drivers’ most noteworthy benefit is reduced change-over times. In many cases, change-over has been reduced from 2 hours to 15 minutes.

United Gear manufactures gears and related power-transmission parts commonly used in over-the-road and off-road equipment, including spur, helical, bevel, spline and internal gears. Altogether, the company estimates that it sells about 1.5 million gears per year to customers such as Eaton Hydraulics, Allison Transmissions, Caterpillar, John Deere and Mack Truck.

The company also does a substantial amount of shaft work. The shaft work, as well as other turning work, primarily uses barstock. Barstock is processed with the Neidlein face drivers and the recently acquired Neidlein live center. Diameters typically range from 1 to 5 inches, with lengths varying from 8 to 38 inches.

Keith Mallek, applications engineer at United Gear & Assembly, says that the company added its first face driver about 10 years ago.

“Since then, we’ve picked up a significant amount of work,” he says. “As a result, we’ve purchased more face drivers to meet the increasing demand for the types of gears that we produce on these machines.”

Originally using face drivers on just a few projects, the company now employs them a great deal more. Mr. Mallek explains that this is because the additional work lends itself to face drivers. They function as a viable alternative to chucking on some gear applications, the company says.

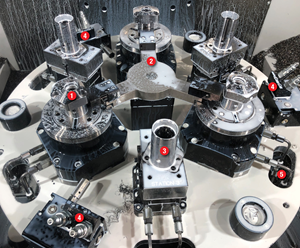

Mr. Mallek reports that the company has experienced no problems with its face-driving applications as of yet. United Gear & Assembly has three standard Neidlein units: models FSB-1, FSB-01 and FSB-4. The company recently added a fourth model that is specially designed to manufacture one particular part family.

“Primarily, we work with 8620 and 4140 steels,” Mr. Mallek says. “We also run 4340, which is quench and temper material that’s usually around 32 to 38 Rc. We use the standard drive pins in our face drivers, which are compatible with these materials.”

Many part orders are recurring. The company typically runs lot sizes ranging from 100 to 1,800 pieces. Machines operate in three shifts, 6 days per week. The change-overs fluctuate daily—roughly ranging from two per day to one every 3 days.

On one job for a particular customer, the company uses double chisel pins on a special face driver designed by LMC Workholding. This is a new application for an old job that required a custom solution because it exceeded the recommended 3-to-1 ratio related to the drive pins. The part is four times the diameter of the drive, so the manufacturer designed a special face driver. This special driver features custom double chisel pins with two teeth on each side. The face driver holds three pins. The addition of two cutting edges or two chisels on each pin provides six gripping edges, the equivalent of six pins.

“It’s worked perfectly and does a good job,” Mr. Mallek says when asked about the face driver. “We are running two part numbers that are members of the same family of parts on this driver.”

The face drivers are used for about 10 percent of the company’s gear work and for almost 100 percent of its shaft work. The majority of the material that the company runs on the face drivers falls into the 1 1/4 inch to 2 1/2 inch range.

“The face drivers are one more tool we have to meet this growing demand,” Mr. Mallek says. “Right now, we are operating three machines with face drivers.”

In addition to easing part change-overs, the face drivers help reduce scrap rates, according to the company. Mr. Mallek adds that although the company experienced issues with TIR with the former process, it has been able to eliminate that problem and improve throughput.

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More