“Edge Factor” Takes Machining to the Mainstream—in 3D

Show focuses on real-life machining and manufacturing. See the 3D preview at IMTS.

Share

Before he worked in film, Jeremy Bout worked in a machine shop. He had the same thoughts about machining that a lot of us have had. Namely: CNC machining is amazing, its precise and complex motions are downright cool, the people engaged in machining play a vital role, and the work of CNC machining deserves to be better understood by the public at large.

Mr. Bout, now an independent film producer, decided to take those impressions and turn them into something real.

The result is “The Edge Factor,” a show that will highlight the real-world applications of CNC machining. The show aims to share the excitement and challenge of manufacturing and metalworking with a mainstream audience. Mr. Bout and the Edge Factor team will soon release a 3D pilot episode that they hope will help them win commercial broadcast on television. Meanwhile, the show will soon premiere online with the launch of that first episode at edgefactor.com. You can see the 3D preview of that first episode at IMTS, where it makes its debut in the Advanced Manufacturing Center, Booth W-160.

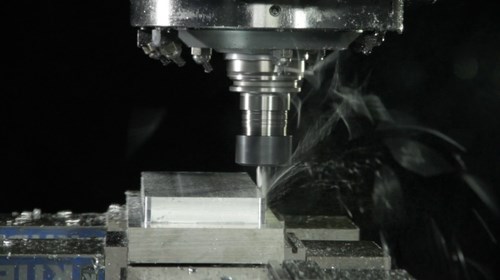

As the energy of the preview makes clear, the show does far more than just dryly teach about machining. 3D footage inside the machine tool captures the drama and beauty of CNC milling, while footage of machined parts in action connects machining both to daily life and to the most demanding applications.

For the pilot episode, the subject is a custom-machined camera-mounting rig that was needed to let a helicopter perform aerial 3D filming of jet boats on the rapids of the Niagara River. Early on, the team’s idea for the first episode centered on a steering-related part used in these boats. However, when Mr. Bout and director Francois Driessen faced the challenge of filming these boats from the air using new 3D camera technology, they realized they would need a mounting boom that did not yet exist. Mr. Driessen, an experienced director who is also very technically and mechanically minded, was able to sketch a detailed design of the rig assembly he would need. He then had to get the parts made. At that point, a light bulb went on.

“We were living an Edge Factor episode,” Mr. Bout says.

He and Mr. Driessen decided then to focus the pilot episode on the making of these very components. The team filmed the machining work at Myles Tool, a machine shop in Sanborn, New York. Telling the story of the rig allowed the episode not only to introduce CNC machining to mainstream viewers, but also to introduce them to an important type of machining business—the metalworking job shop.

Modern Machine Shop magazine helps make those introductions. Senior editor Peter Zelinski narrates some details of the camera rig’s story, and will continue to figure into future episodes. Modern Machine Shop hosts The Edge Factor at IMTS, screening the Advanced Manufacturing Center’s 3D preview. Mr. Bout and the rest of the Edge Factor team intend for the complete 3D pilot episode to air in November at edgefactor.com.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)