Published

Don’t Forget Technology

The challenges facing manufacturing are overstated if we don’t allow for technology’s role in the solution.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

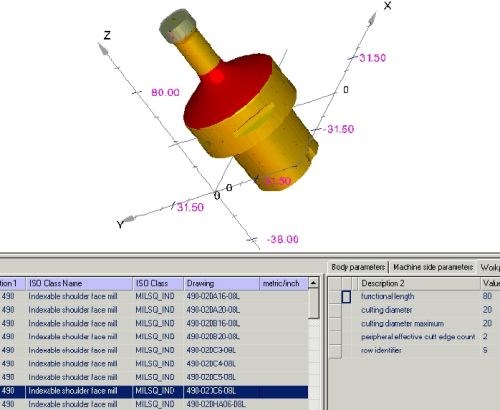

Here is part of a screen capture from the tool-selection software mentioned below. This article provides more information about the development.

Technology has enabled manufacturers to become dramatically more efficient. The advance of control systems has enabled machine tools to perform complex work with increasing speed and precision. The advance of information systems has enabled manufacturers to compress lead times and inventories. In manufacturing, technology has come so far, so fast, that it seems unrealistic to expect technology to keep delivering radical transformations at its recent speed.

But what if the pace of change does continue? More conservatively, what if technology delivers radical transformations at just some fraction of its recent pace?

Manufacturing technology is still moving. Some of the changes that are near enough for us to guess at them promise noteworthy leaps. For example, software relying on tool standards could automate tool selection. Algorithms relying on 3D scanning (mentioned in this article) could automate crash avoidance. Both advances would simplify CNC machining. Then, there are the advances too strange for us to guess right now. These will save both time and cost as well.

U.S. manufacturing faces various challenges, one of the more serious of which is a looming and seemingly inevitable lack of capable manufacturing personnel. In the face of this problem, it would be naïve to say, “Technology will save us.” However, it would be just as naïve to say, “Technology won’t play a role.” In fact, technology will certainly contribute to the way this challenge is met. To one extent or another, the amount of manufacturing staff needed in the future will be different from what we expect today.

.png;maxWidth=300;quality=90)