Cutting Tool Manufacturer Grows on Diversification, Automation

A new, heavily automated facility helps Tool-Flo supply new customers with grooving, threading and other indexable cutting tools.

Share

In addition to consolidating operations from four facilities to one, Tool-Flo’s new 88,000-square-foot indexable cutting tool manufacturing plant in Houston, Texas offers room to grow. More specifically, it offers room to automate.

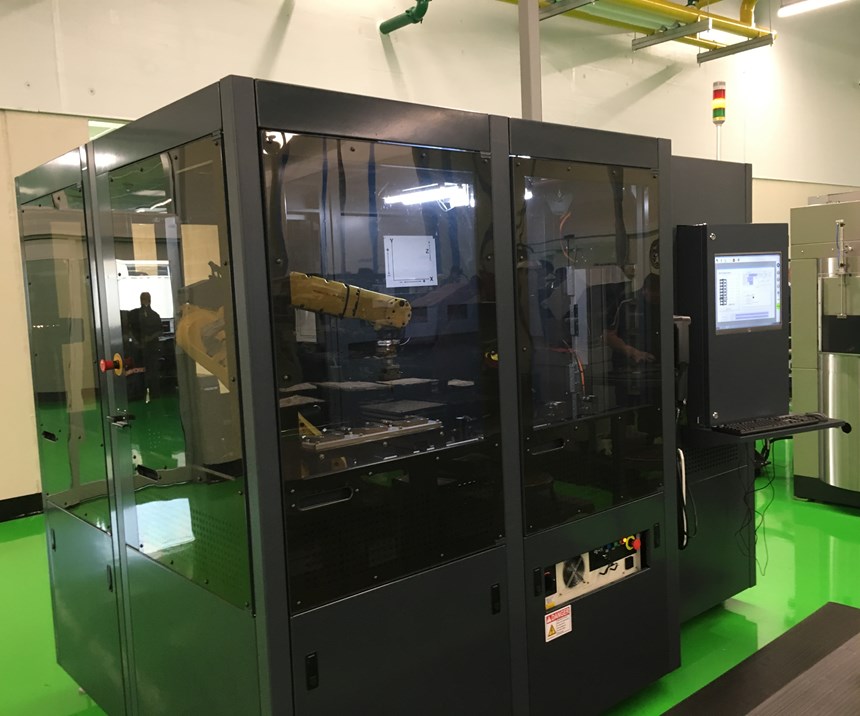

As seen in the photo gallery above, many investments have already been made. Lines of new insert grinders incorporate robot-arm tending so that one person can supervise multiple machines. Processes previously performed manually have also been automated, and new machining resources are available to cut tool bodies.

Much of the company’s recent growth has been driven by diversification into new markets, says Charlie Mendez, advertising director. He credits membership in the IMC Group, a 13-member conglomerate of carbide cutting tool manufacturers, for helping the company expand its focus beyond energy and its customer base beyond Houston, and for helping facilitate investments in facilities and equipment.

Consolidating the operation brings benefits as well. Productivity, lead time, quality and service are expected to improve, as are internal communications between sales, engineering and manufacturing. Scroll through the photo gallery above for a look inside the new plant.

Related Content

-

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.png;maxWidth=300;quality=90)